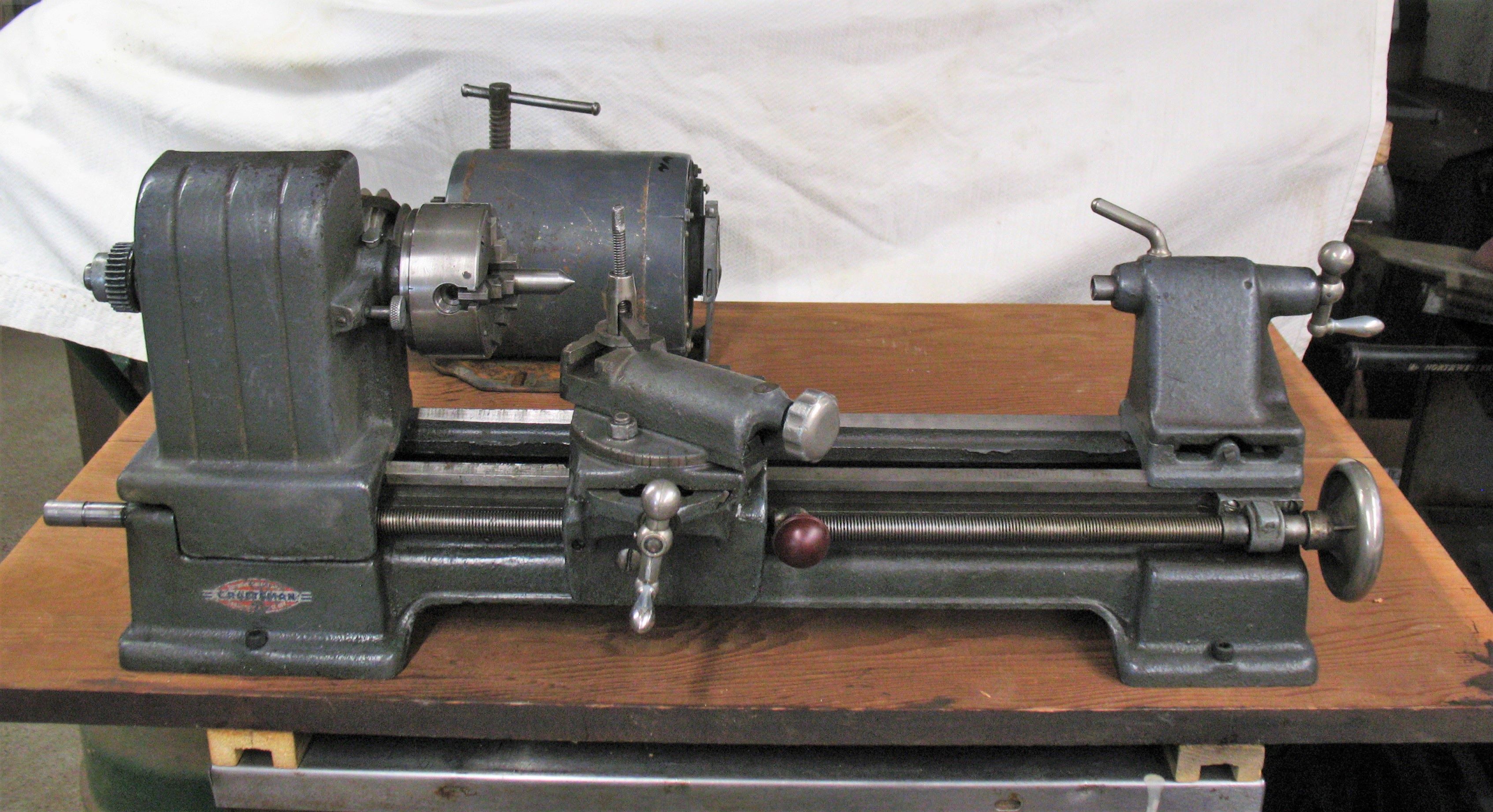

This is what I started with.

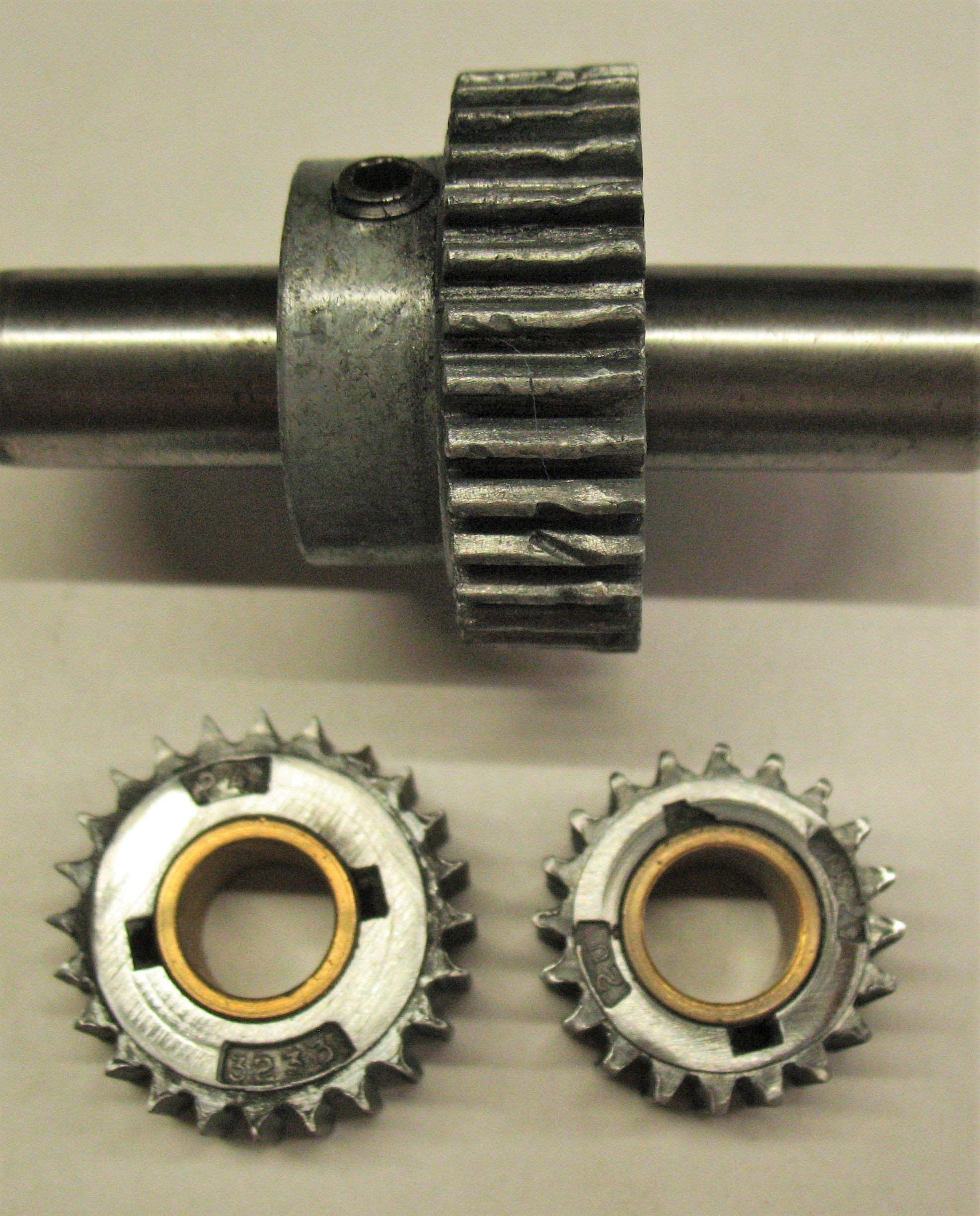

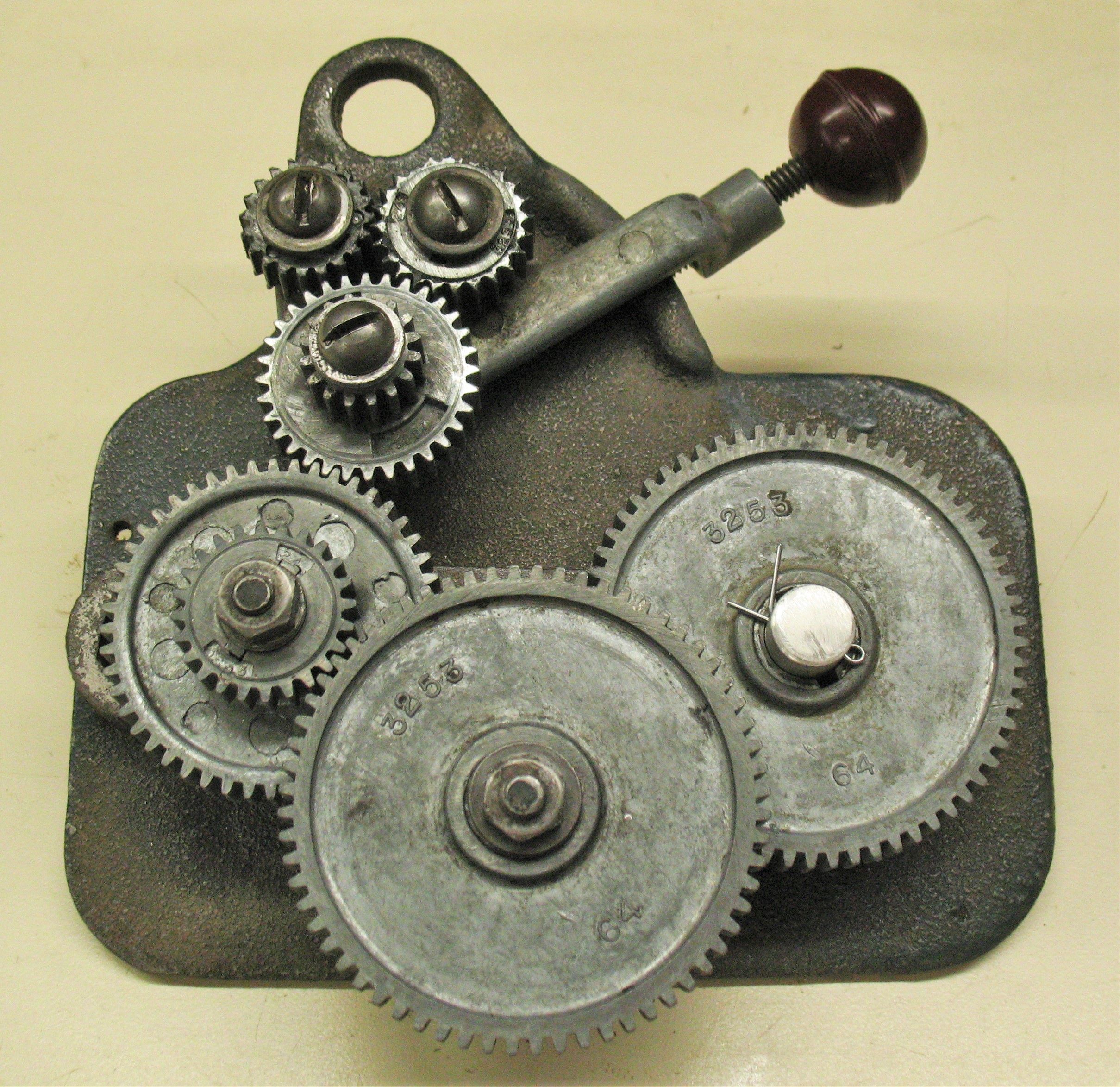

Gear Train For Carriage Movement and Gear Cutting.

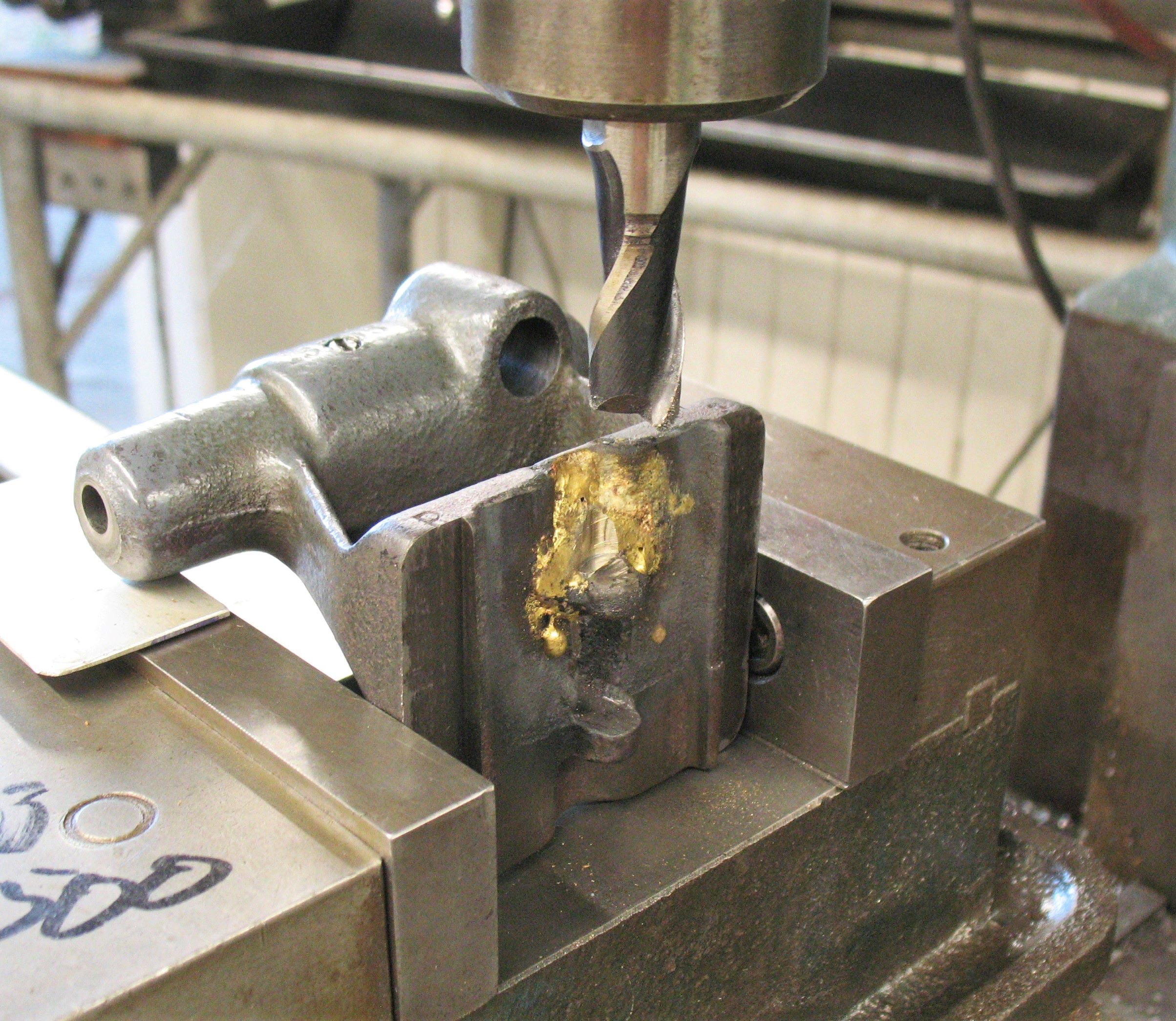

Damaged Gears

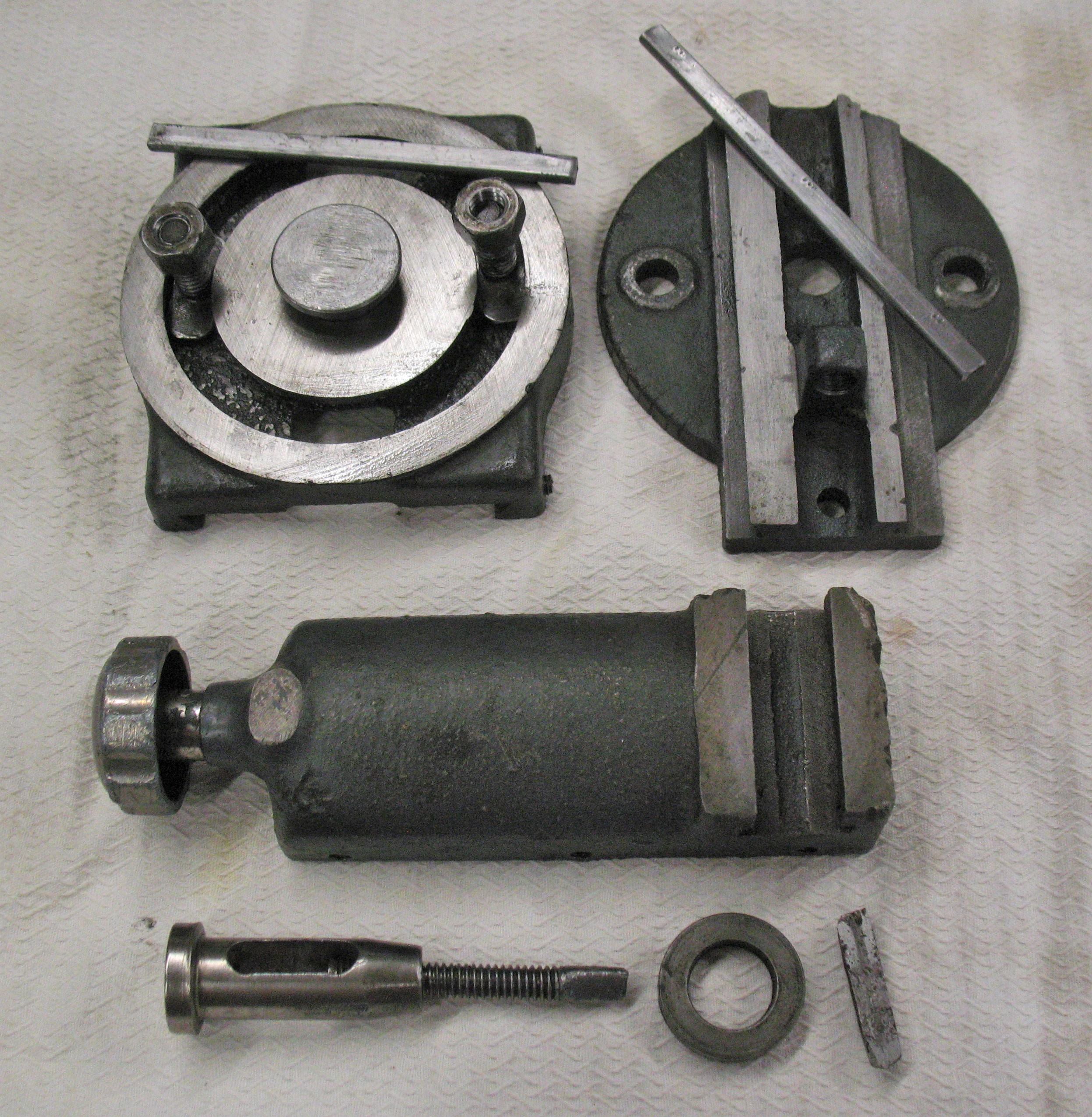

Remove Spindle, Back Gear and Pulley. Cleaned Casting.

Back Gear Housing

Cleaned Spindle, Back Gear and Pulley.

Reassembled Spindle with New V Belt.

Took 4 Jaw Chuck Apart and Cleaned It.

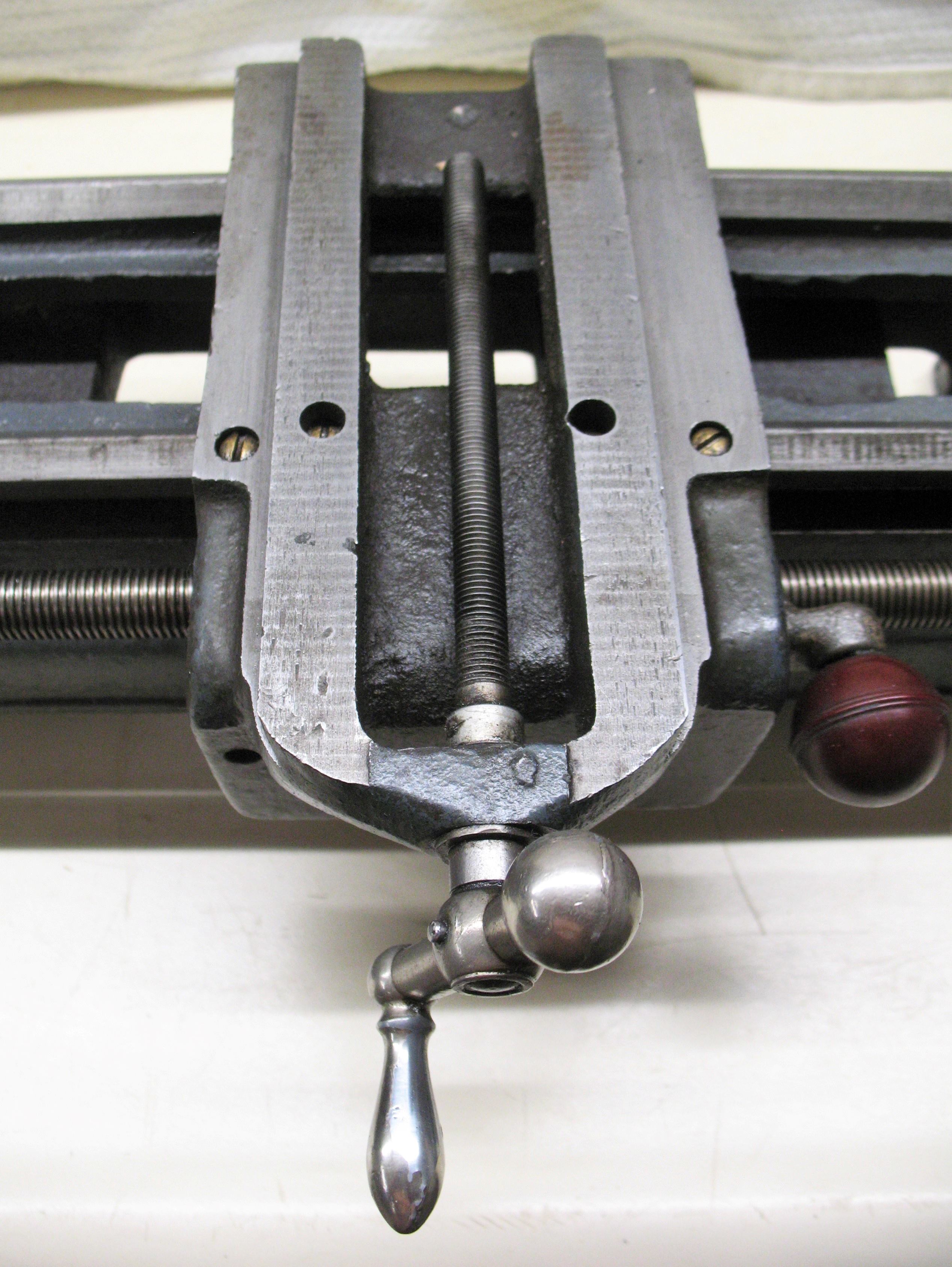

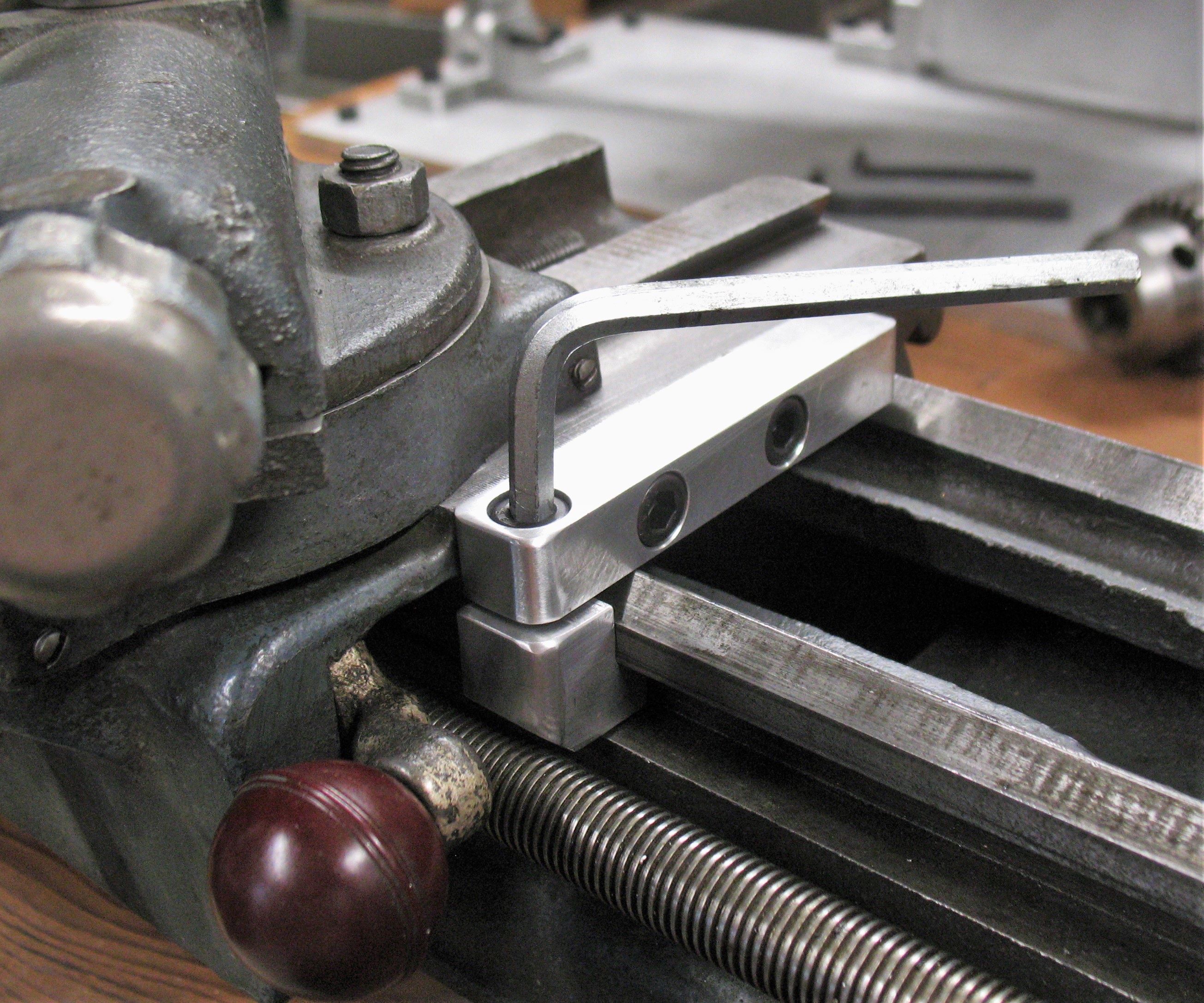

Cleaned Cross Slide, Compound and Tool Holder.

Cleaned Carriage.

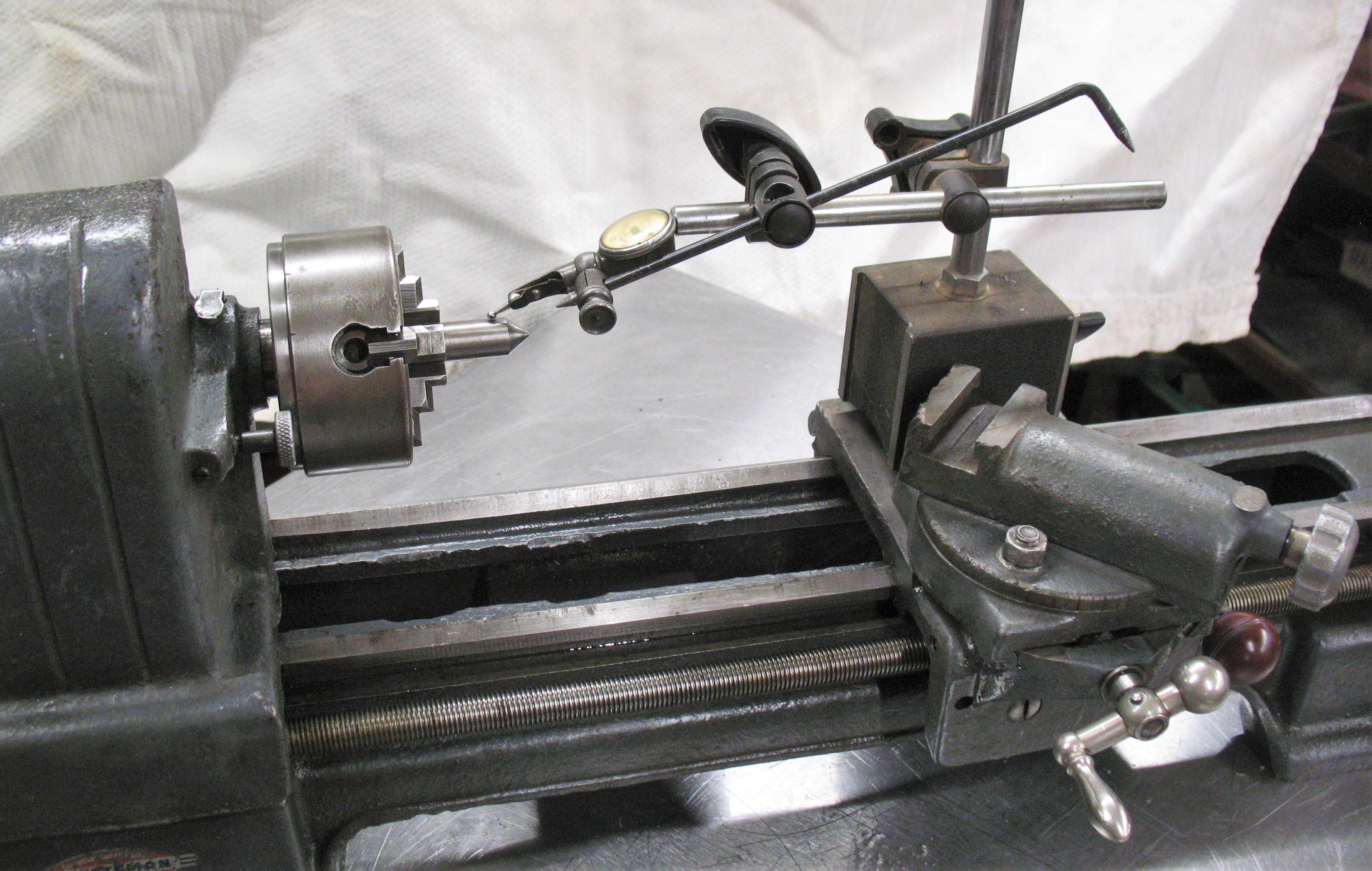

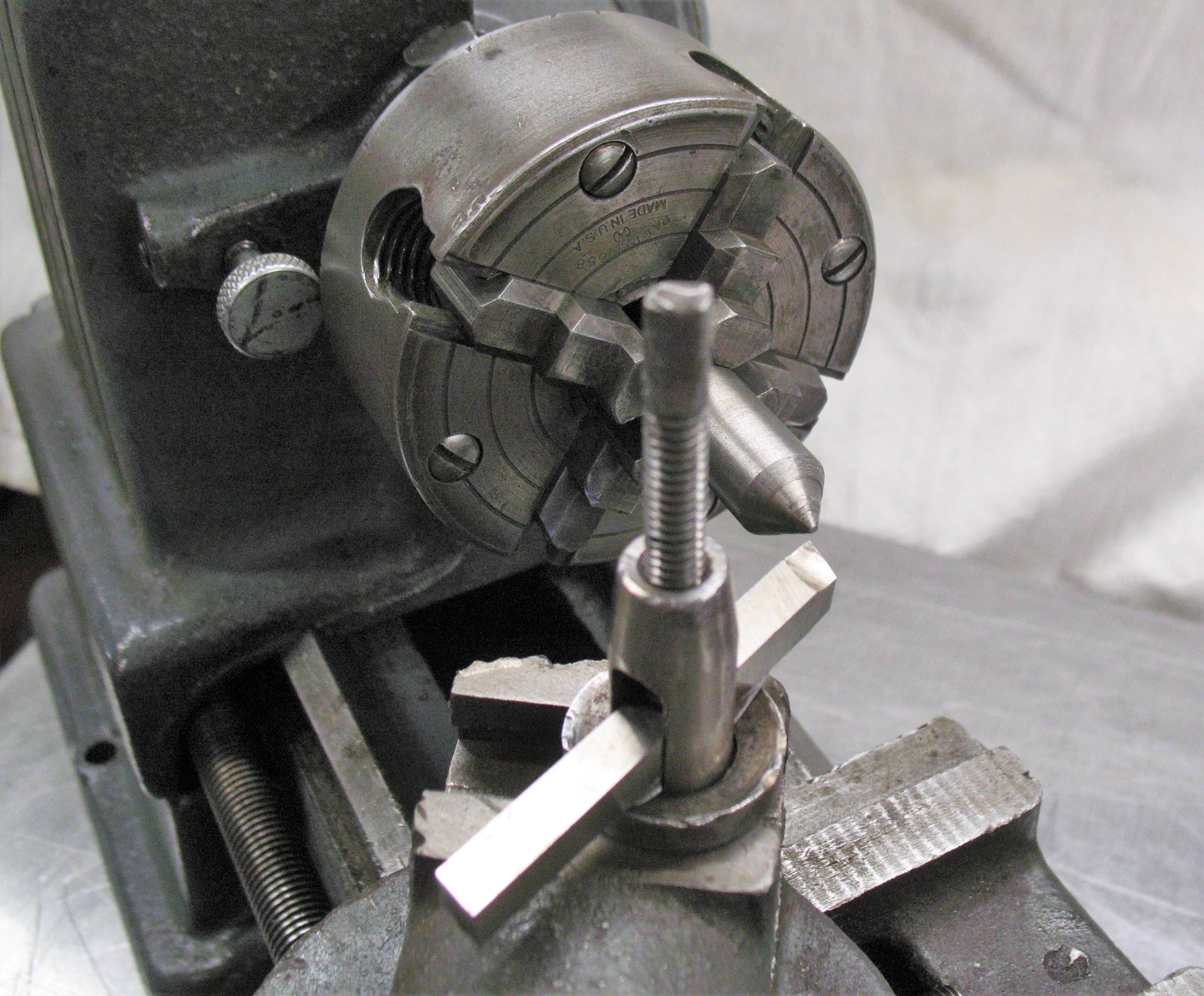

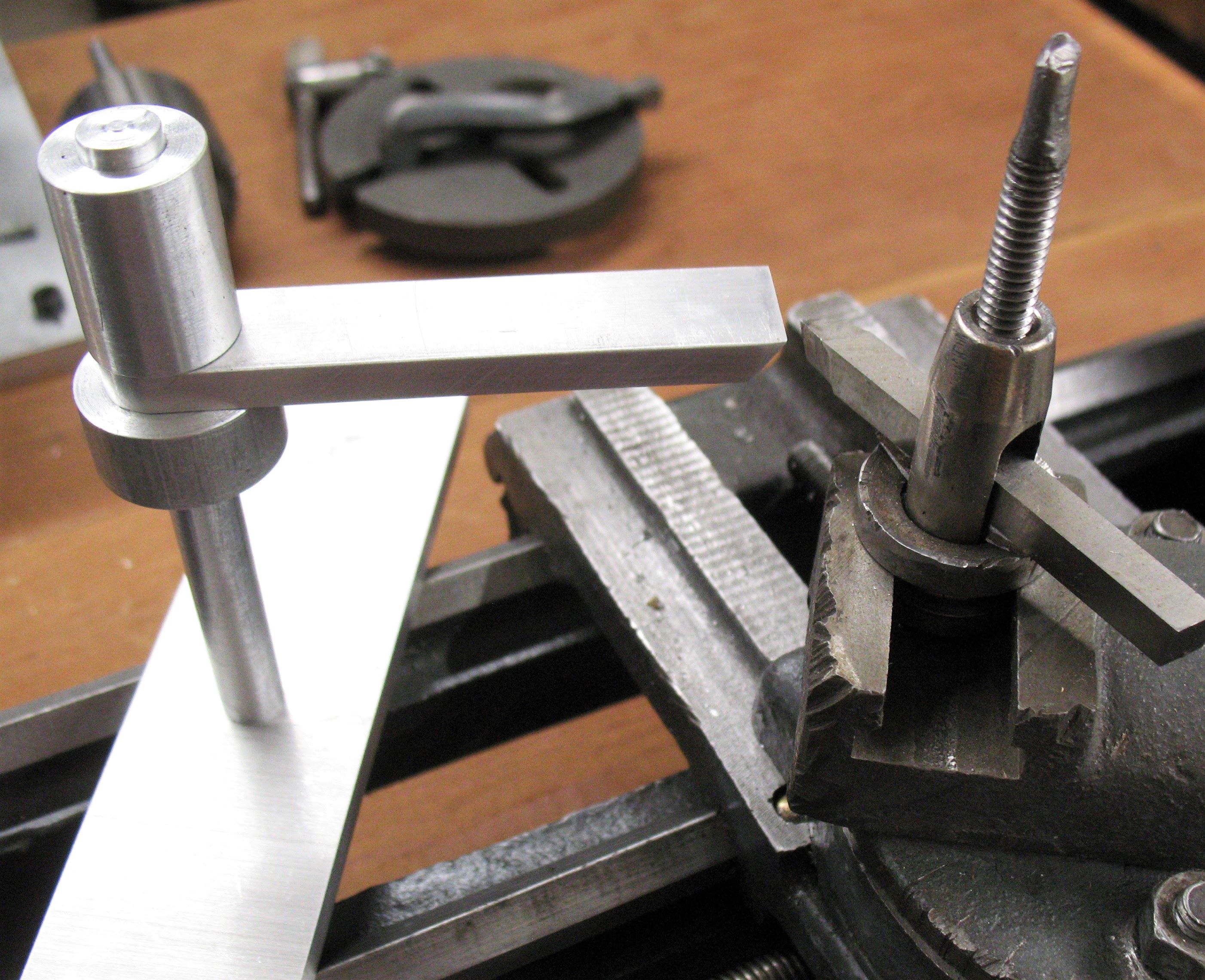

Carriage and Cross Slide Back Together. Dialing in Point.

Setting Tool Height.

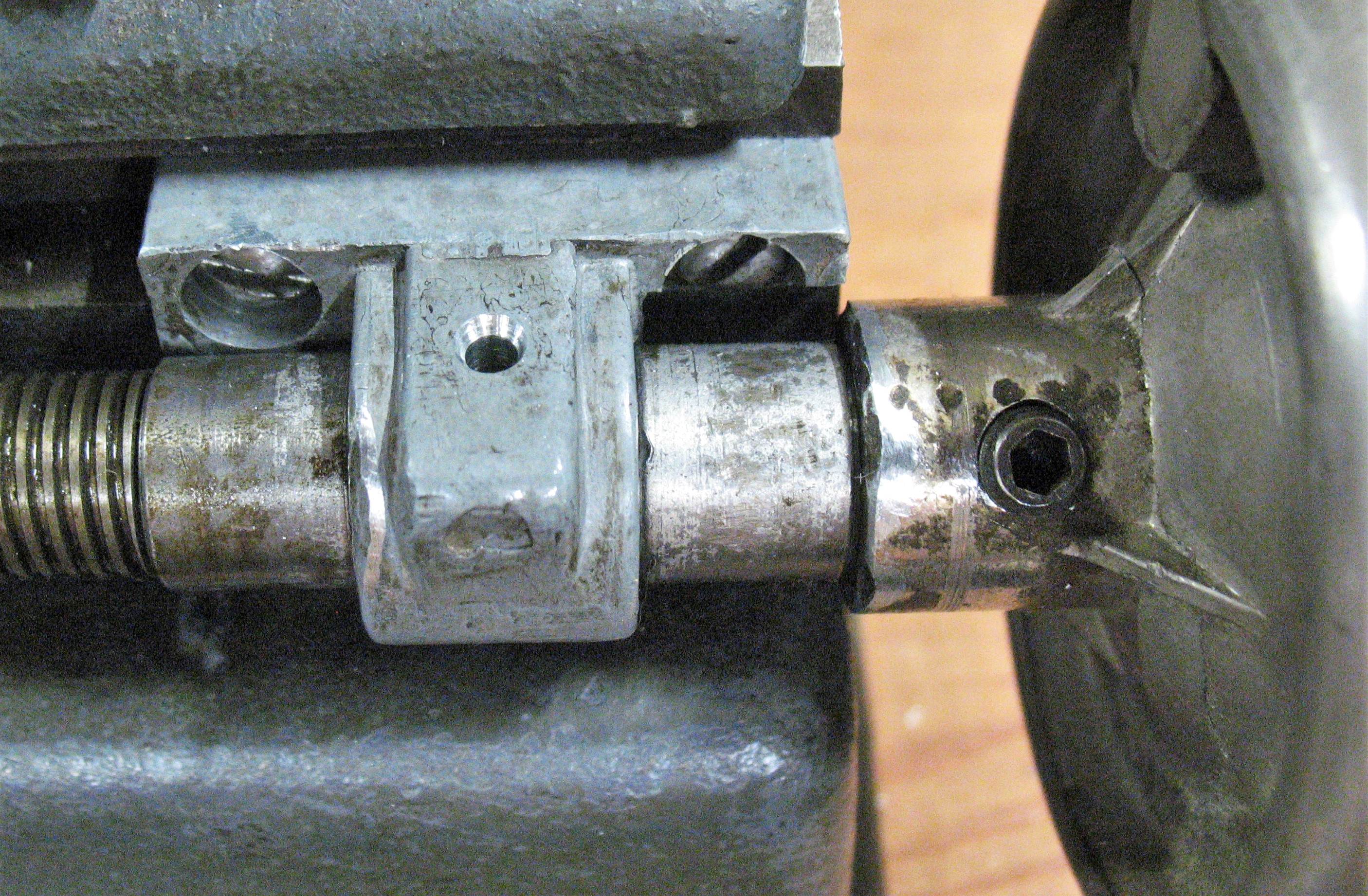

Took Tail Stock Apart and Cleaned. Tail Stock Uses Morse Taper "0"

Fixed an Old Repair, Now it Works Correctly

Tail Stock Back Together.

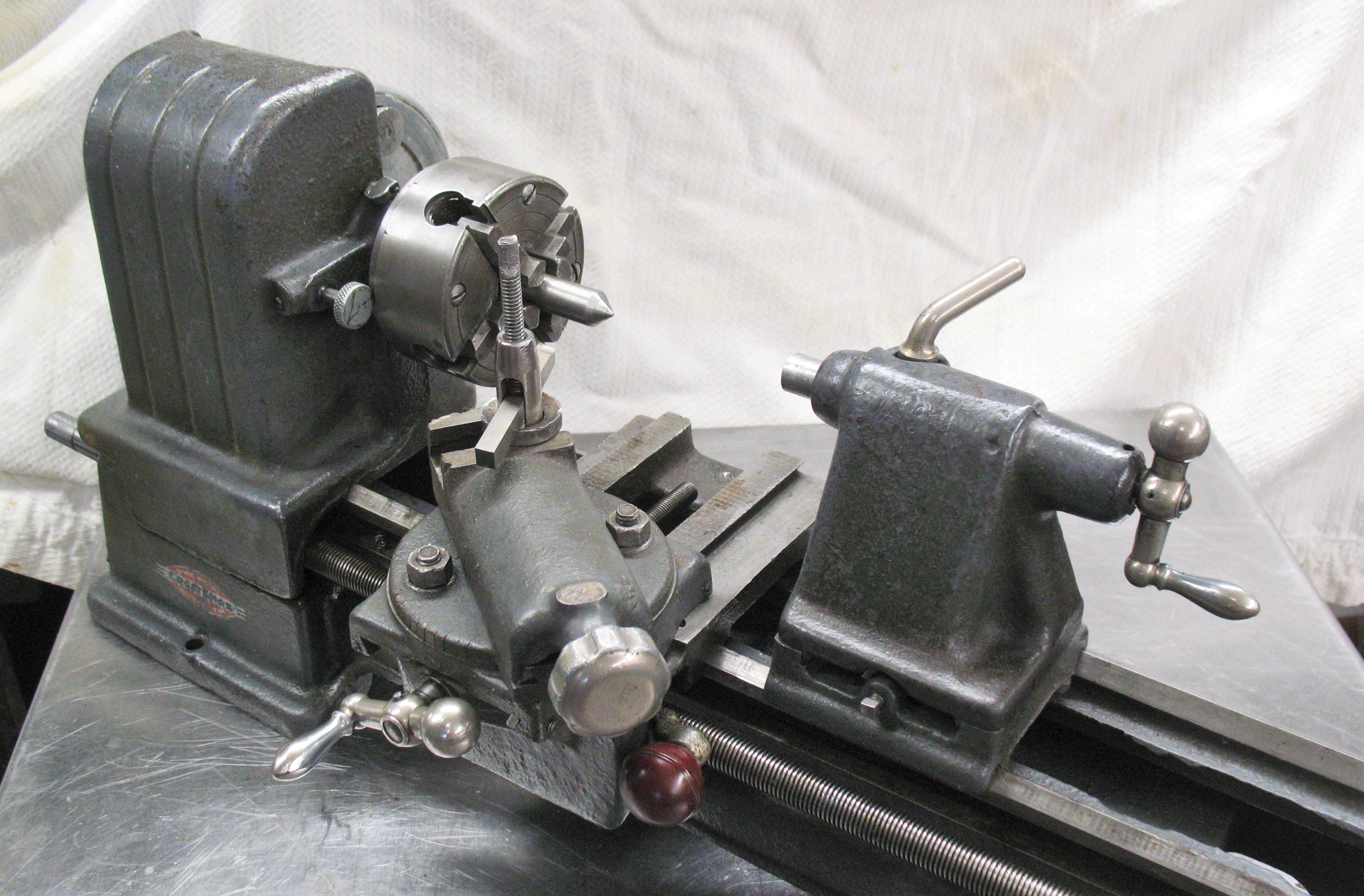

Lathe Mounted On Board

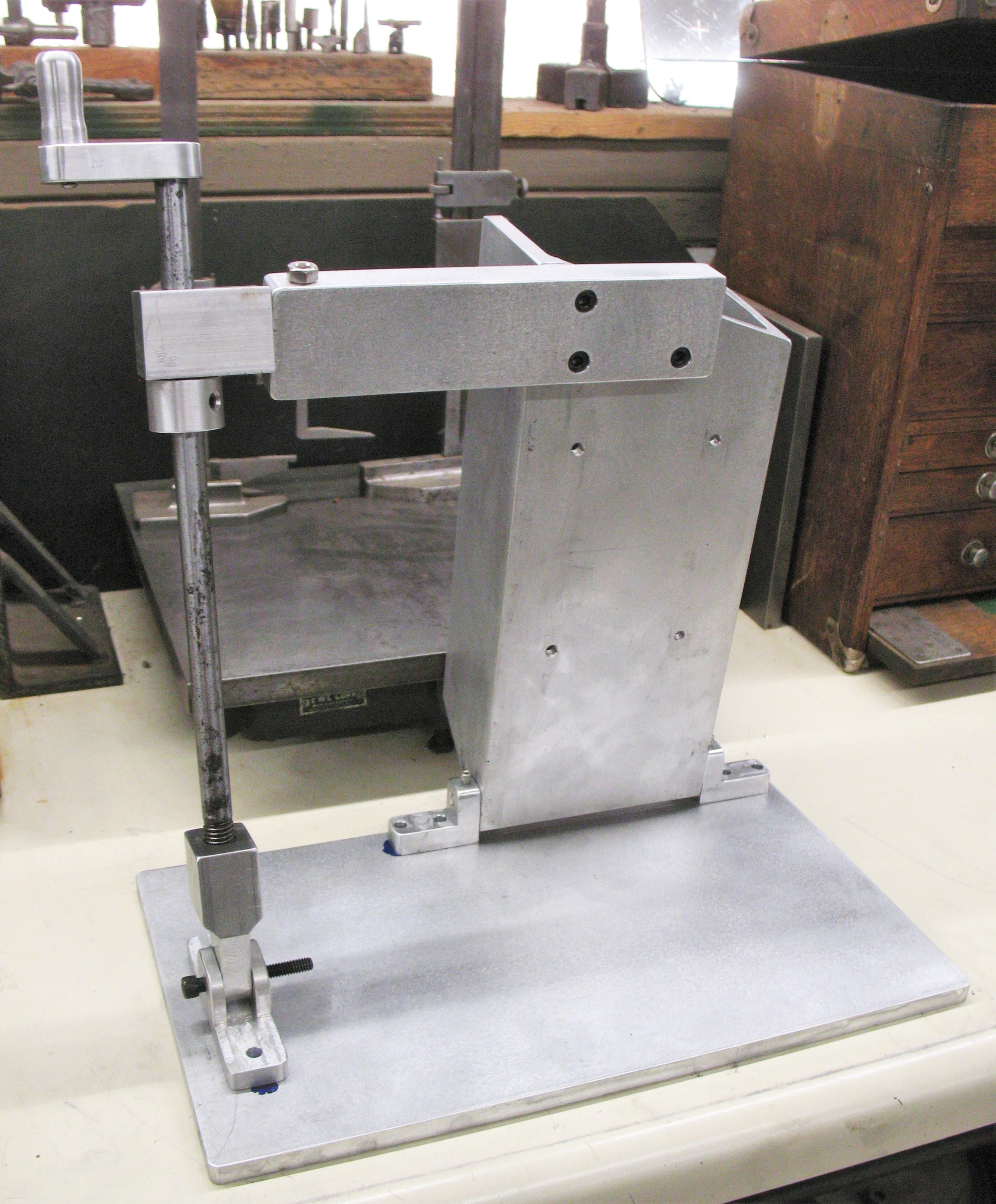

Motor Mount and Belt Tensioner, 12 Parts, 50 Holes and 21 Tapped Holes.

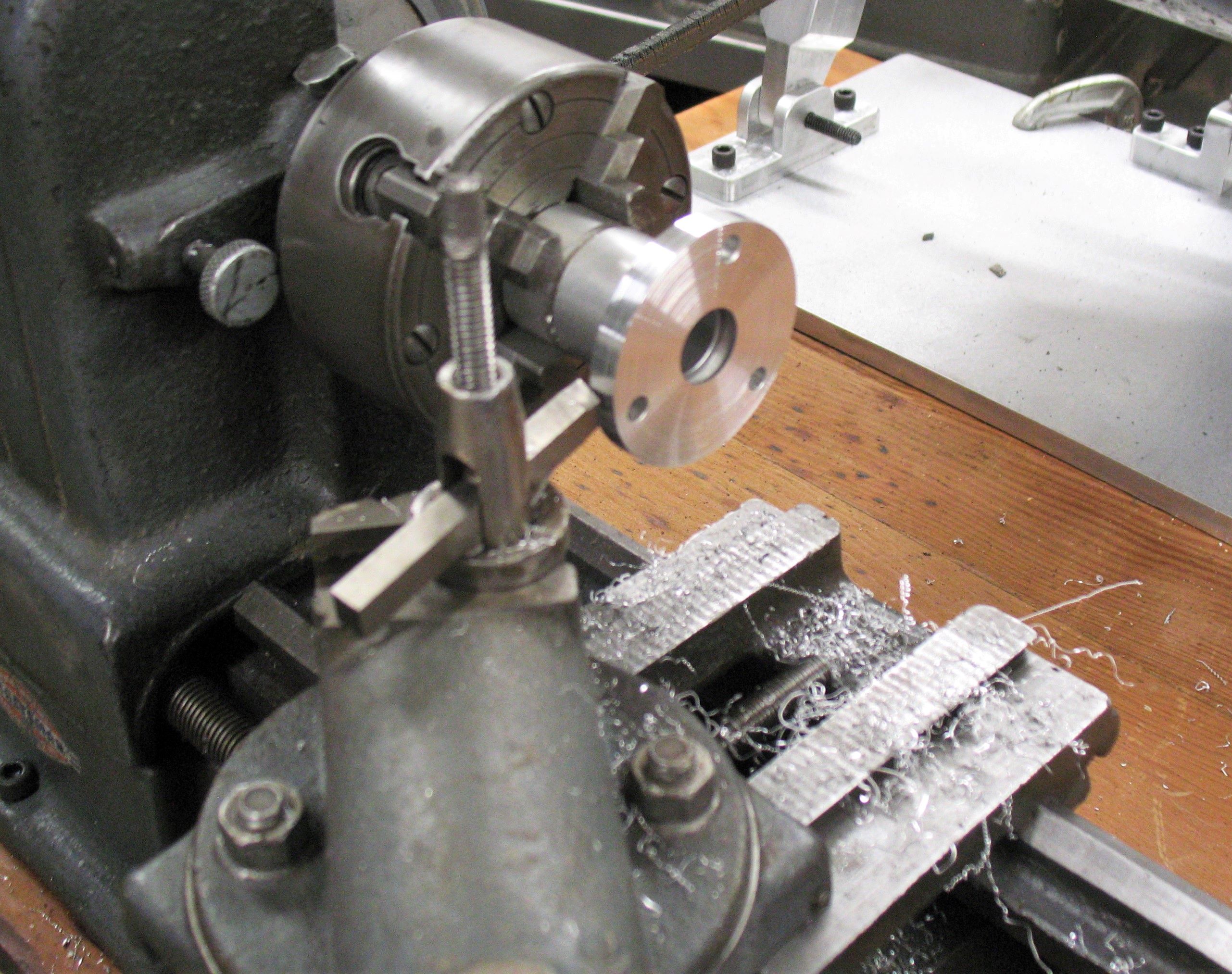

First Chips

First Chips

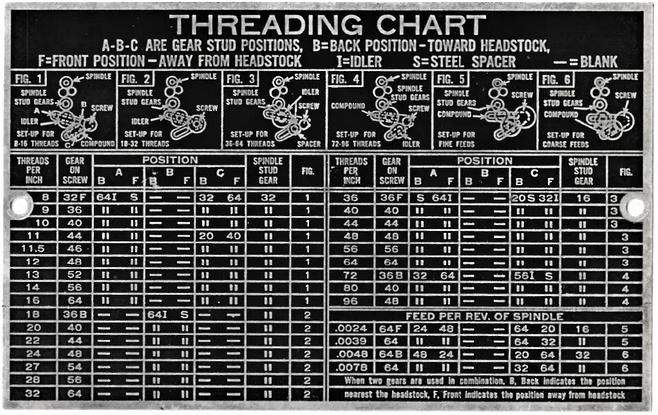

Cleaned and Re-Assembled Threading Gear Train

Made Tool Height Gauge

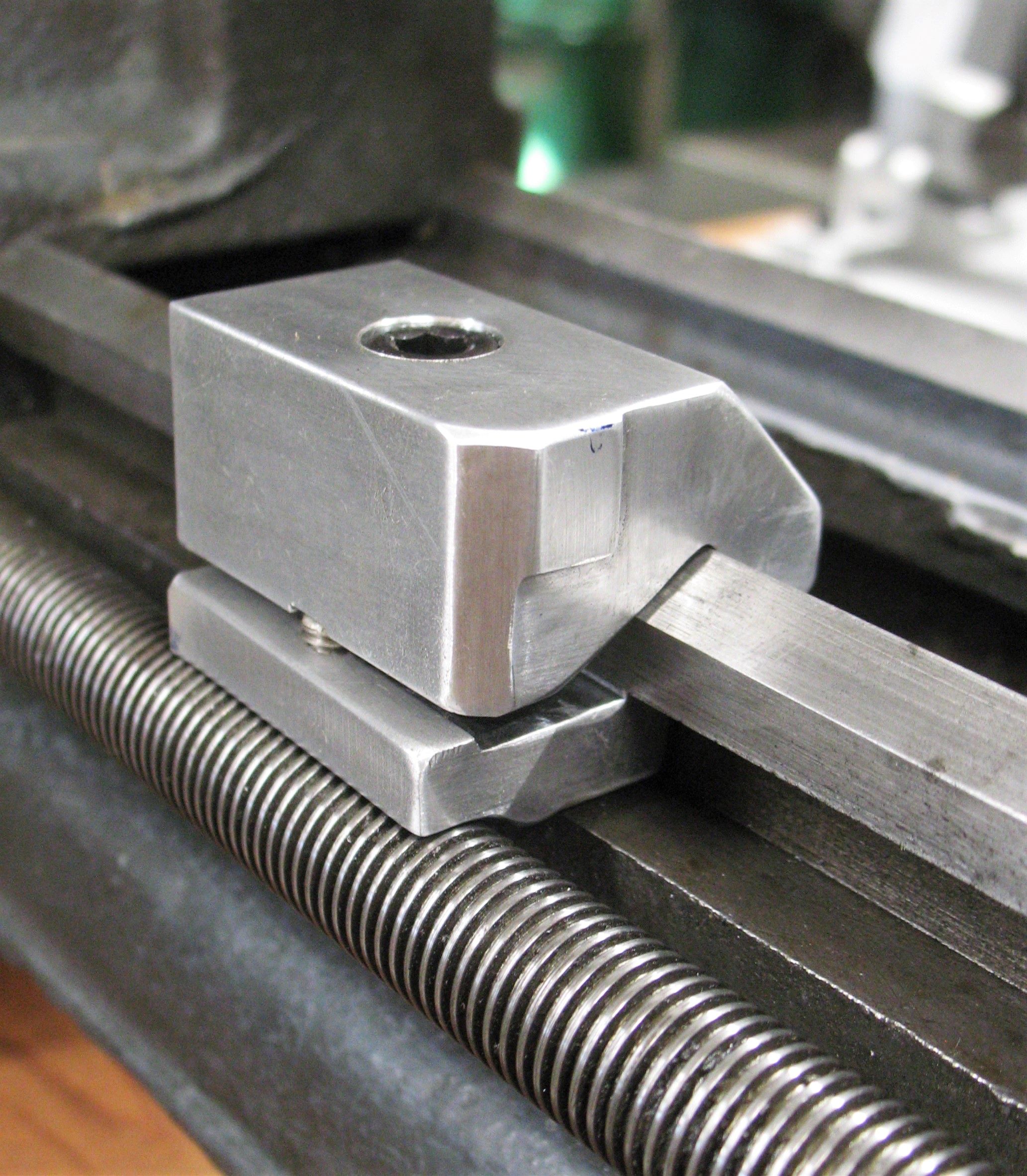

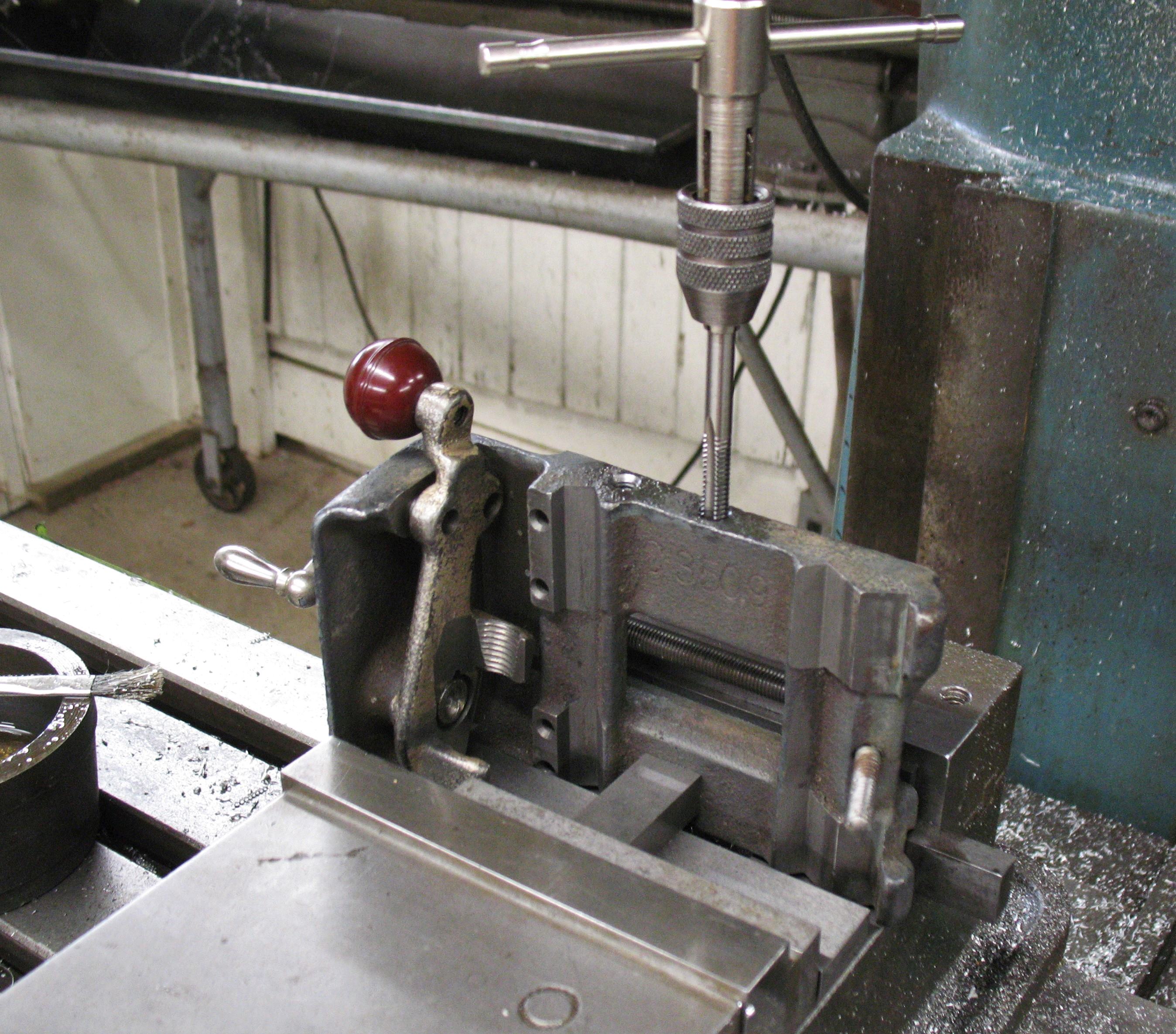

Made a Hard Stop for the Carriage

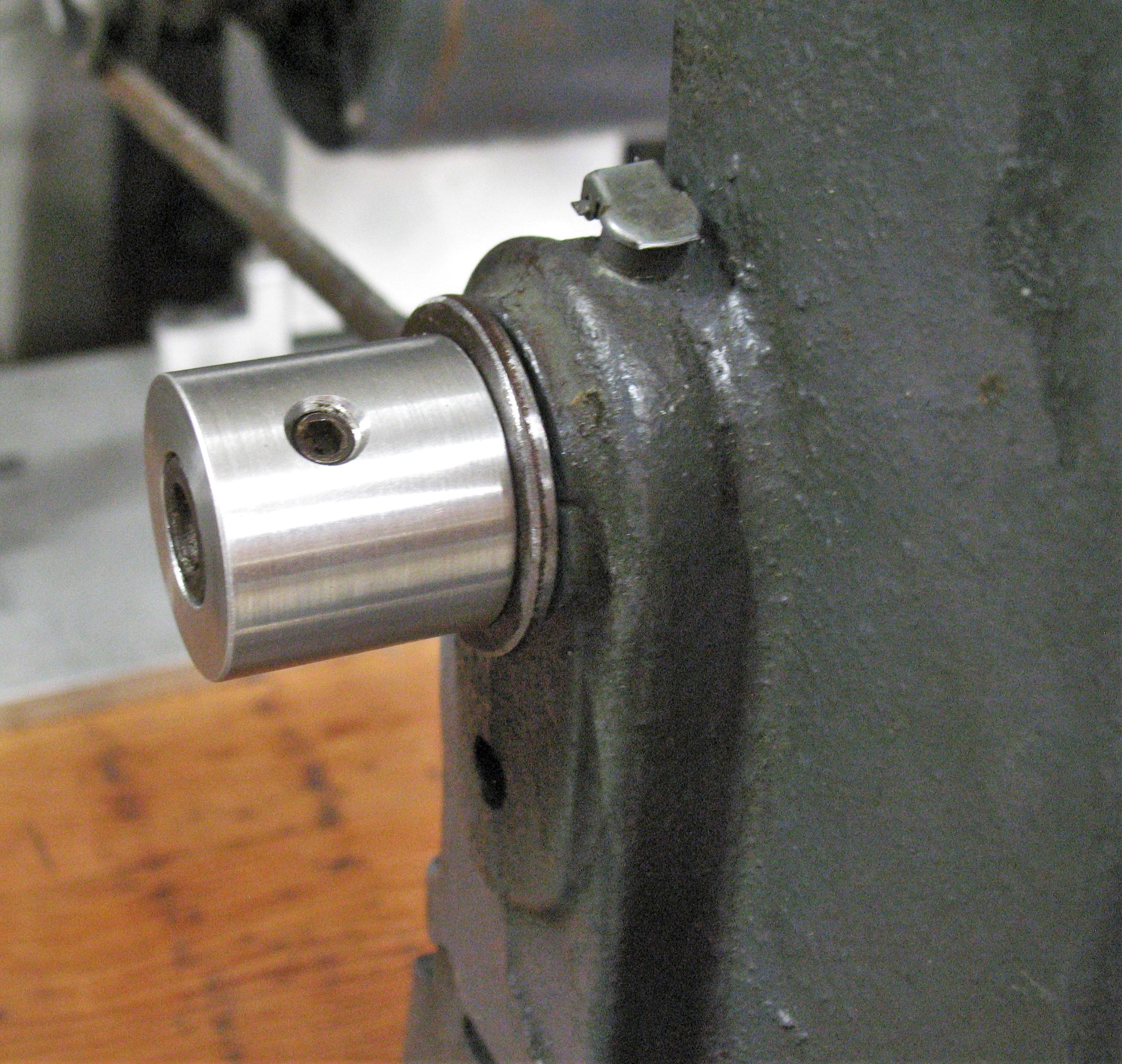

Drilled Holes For Oil in the Lead Screw Bearings

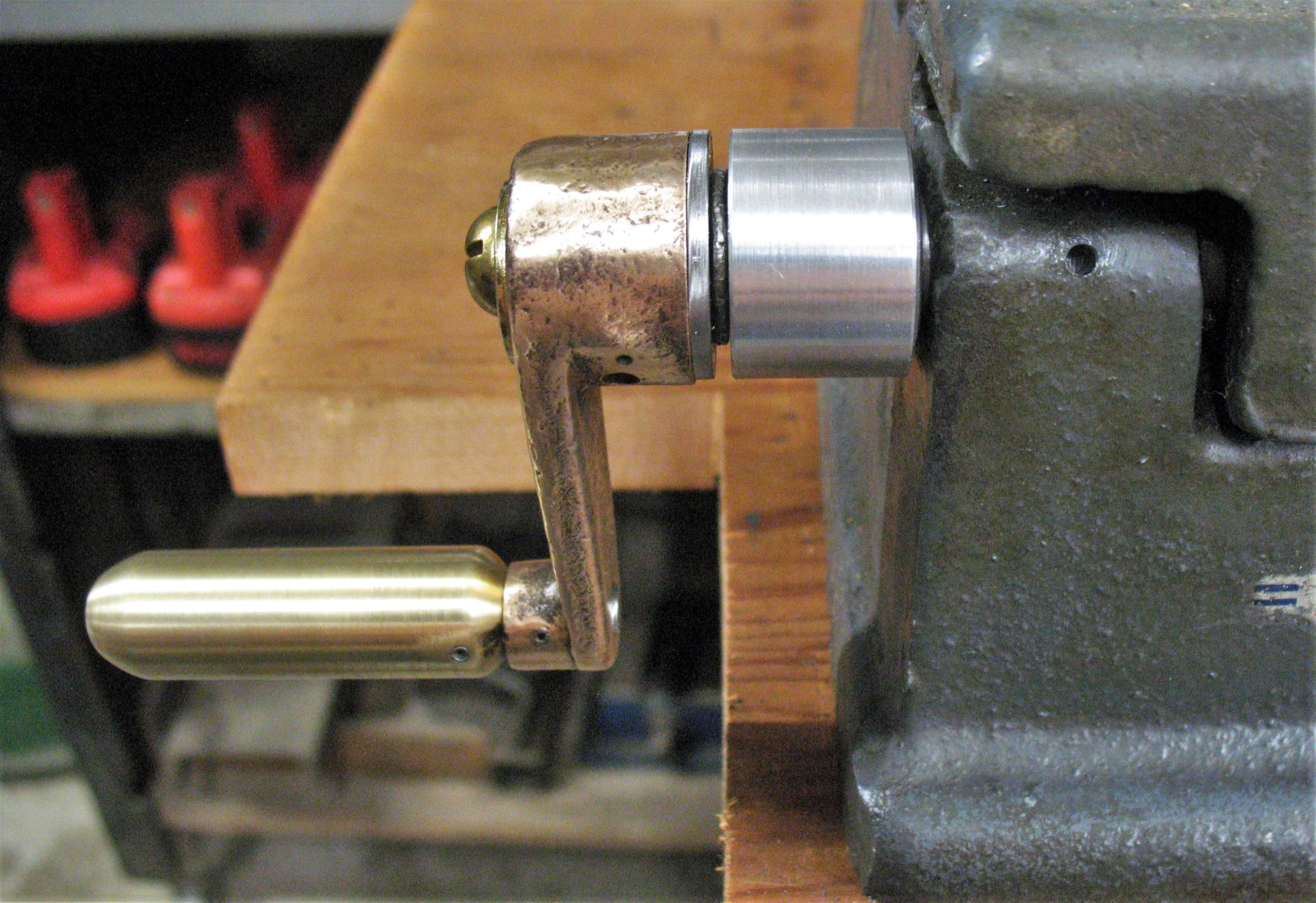

Made a Crank and Spacers for the Lead Screw on the Head Stock End

Made Collar to replace Damaged Spindle Gear

Drill and Tap Holes in Carriage

Made Carriage Lock

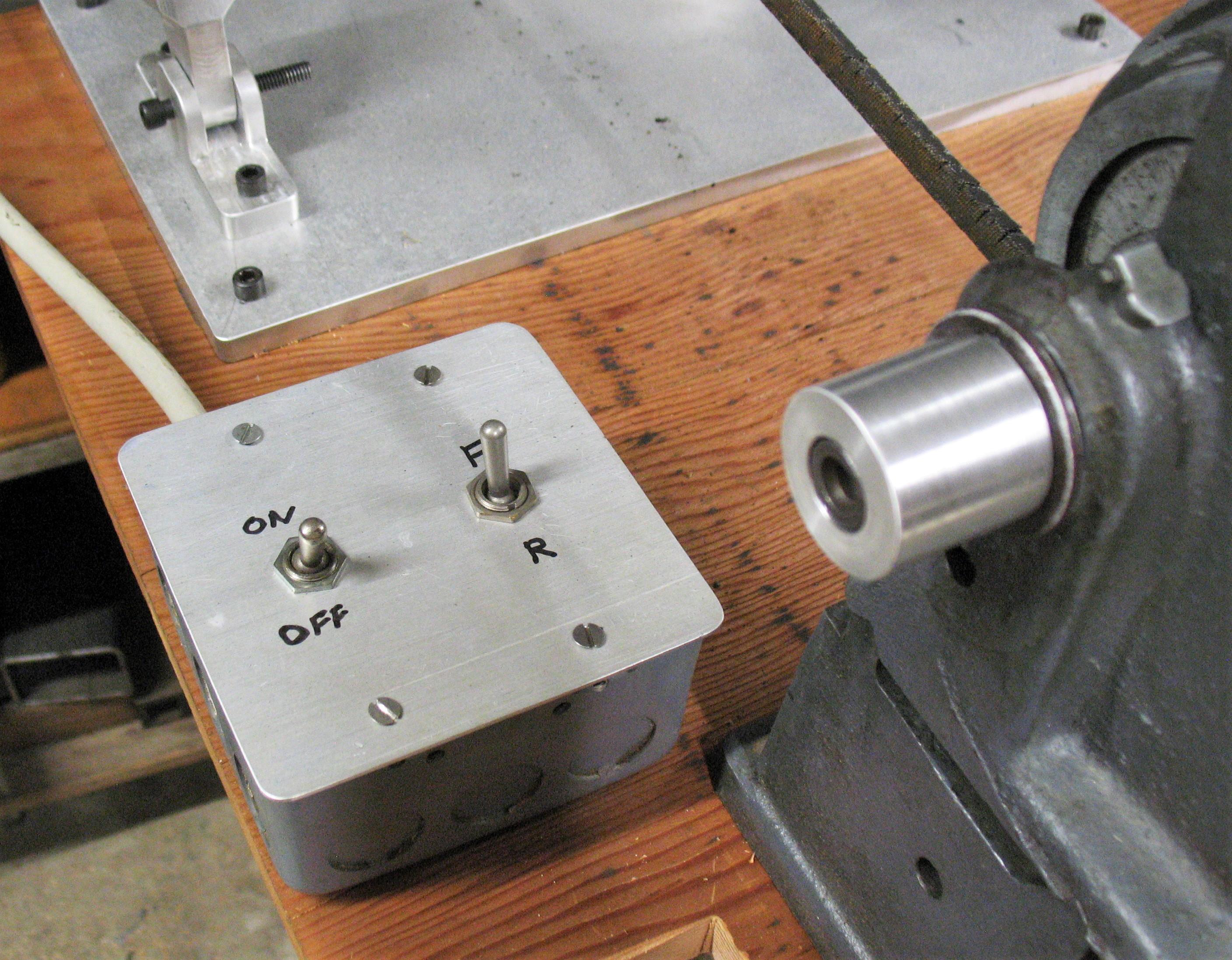

New Power Cable, New Switch Box and New Wire Harness.

Ten Wires and Two Switches. On/OFF and Forward/Reverse.

Cross Slide Moves .040 per turn.

Compound Moves .040 per turn.

Lead Screw Moves .060 per turn.