Enco Mill Repair

Repair Spline Sleeves

Clean Shop

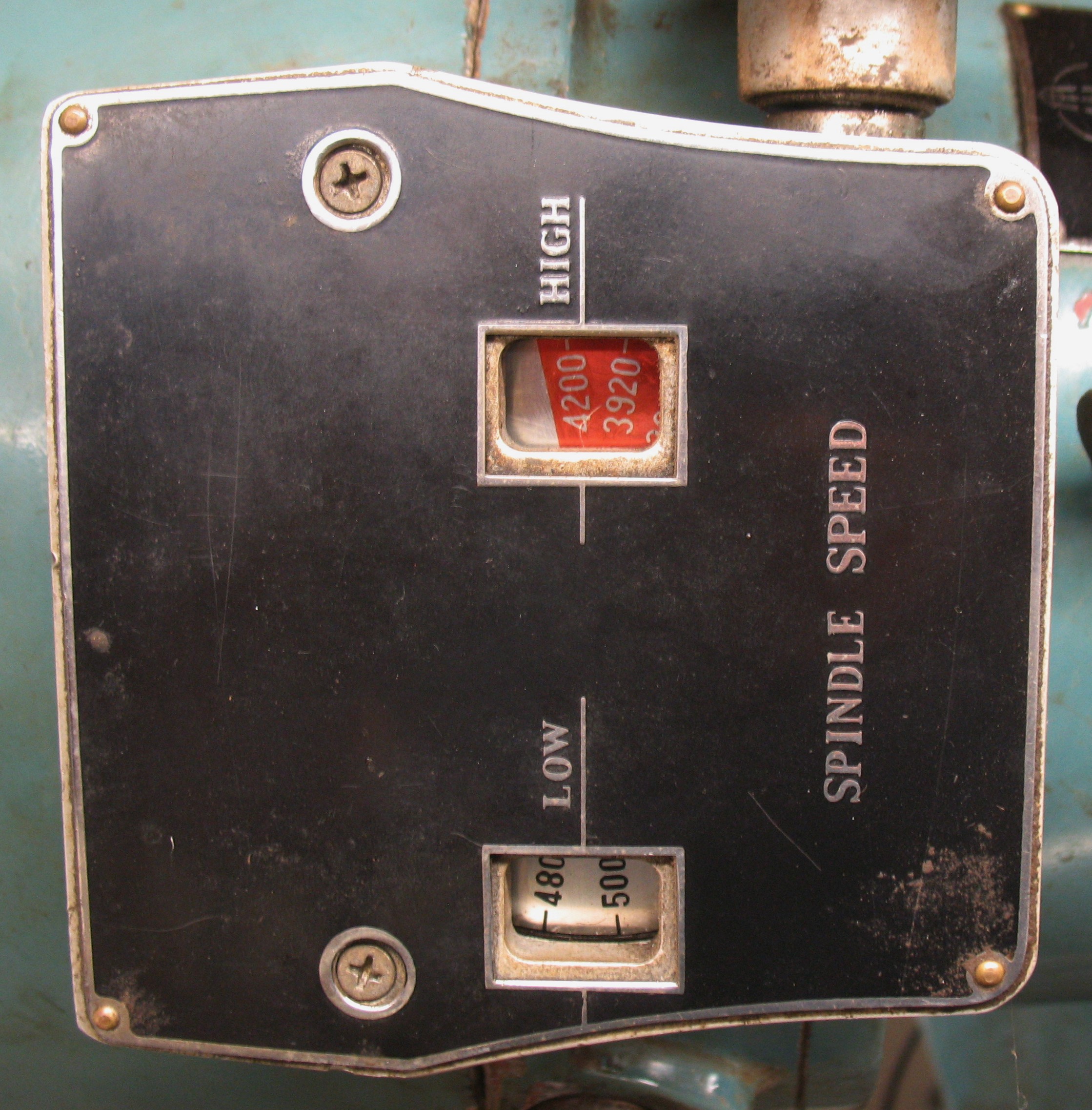

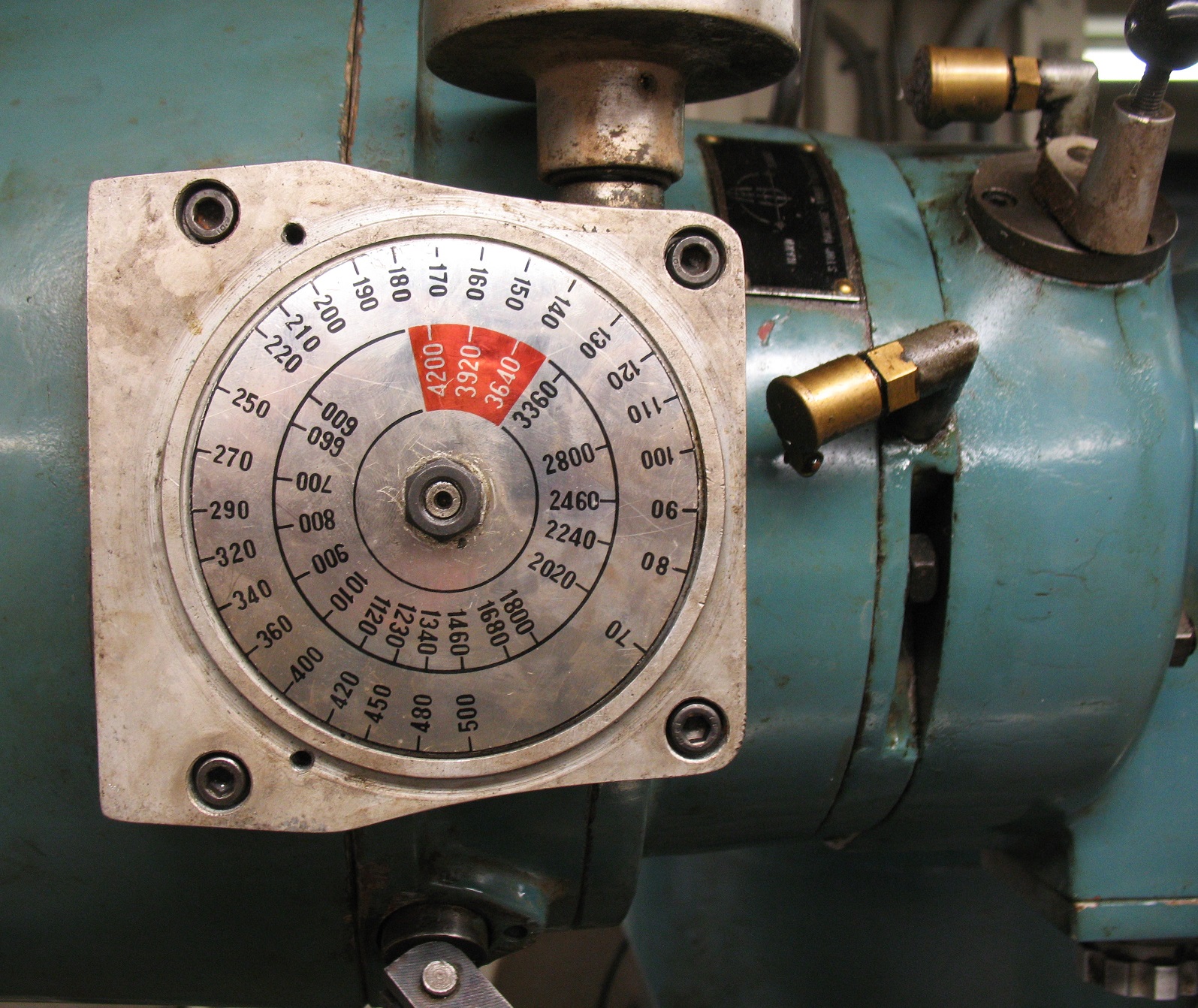

Turn on mill and set the speed to fastest speed.

Disconnect Power.

Remove DRO display.

Remove power direction switch from mill head.

Remove Phase Converter.

Remove Hand crank for boring feed.

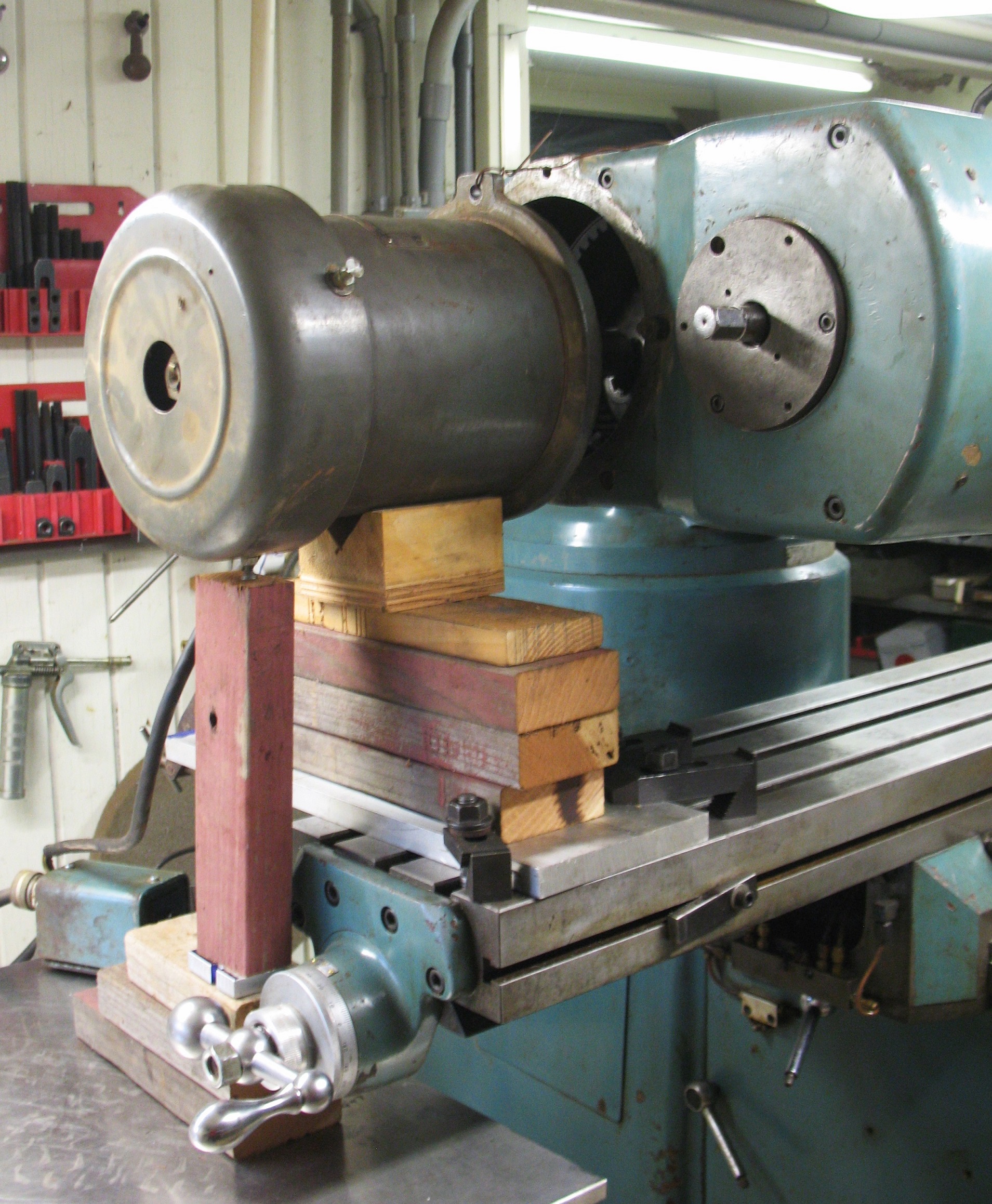

Loose nuts on front of mill head and tilt to left 90 degrees.

Tighten nuts.

Remove bottom motor pulley cover, 3 screws.

Compresor Details link

Disconnect Power.

Remove DRO display.

Remove power direction switch from mill head.

Remove Phase Converter.

Remove Hand crank for boring feed.

Loose nuts on front of mill head and tilt to left 90 degrees.

Tighten nuts.

Remove bottom motor pulley cover, 3 screws.

Compresor Details link

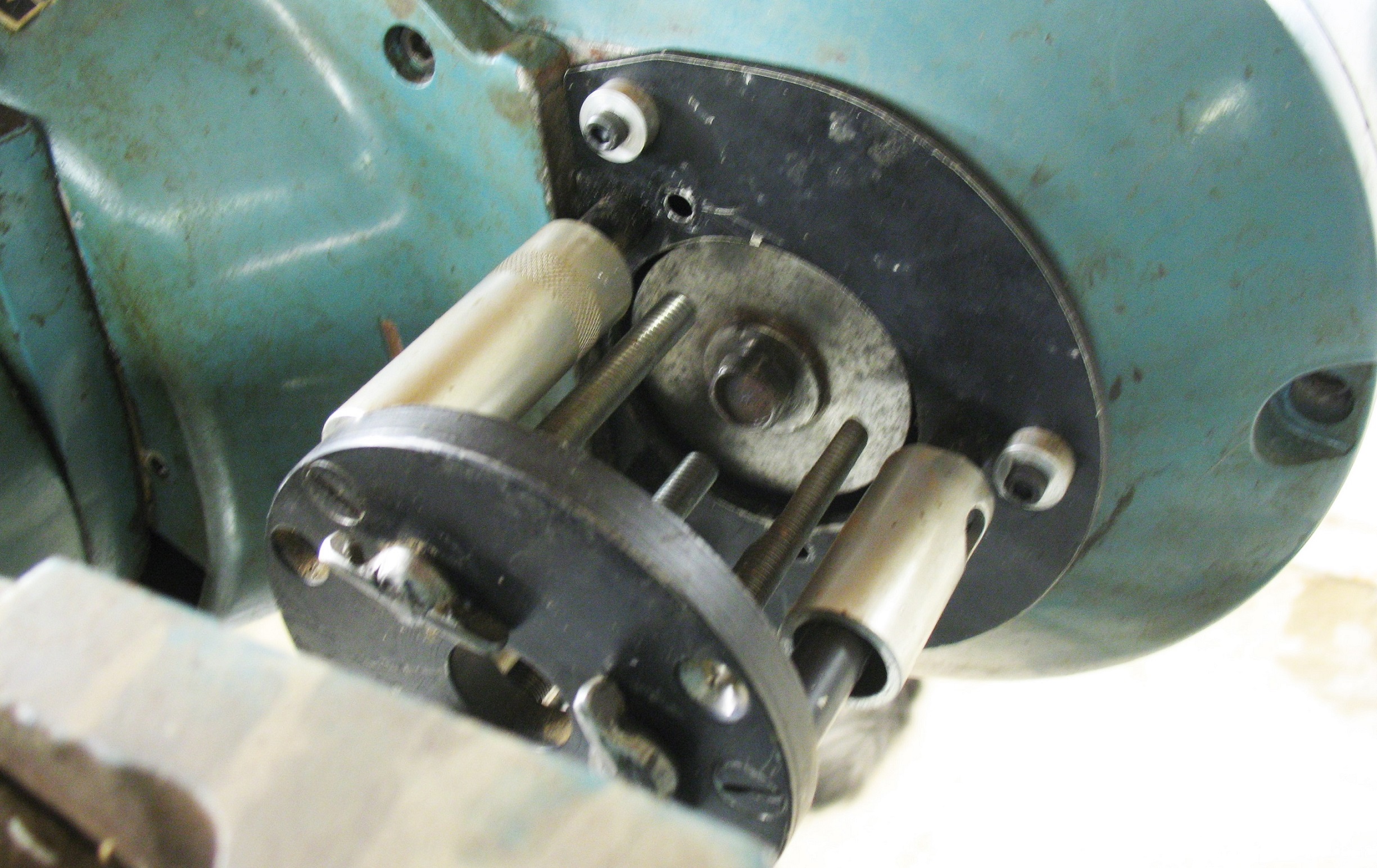

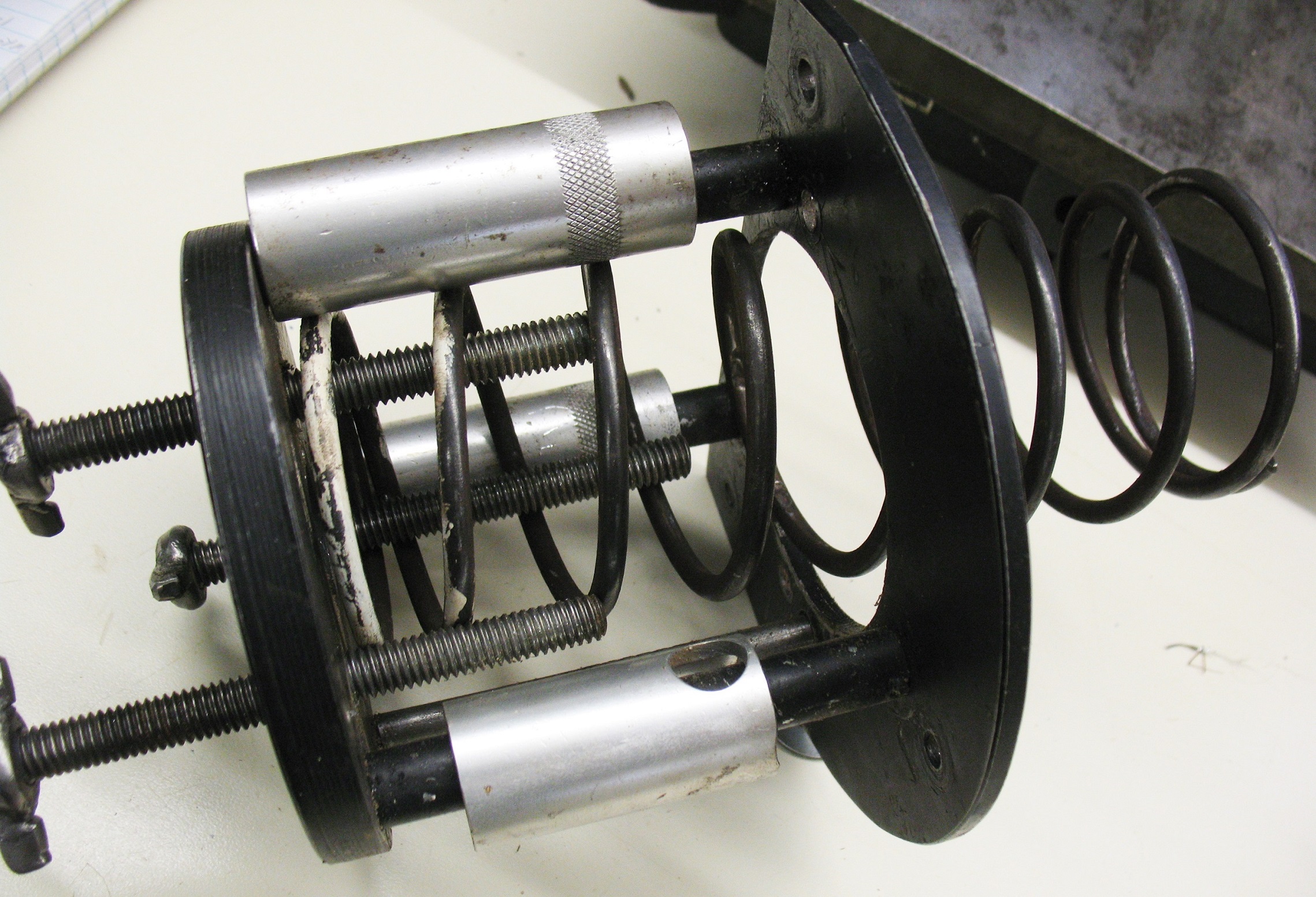

Mount Spring Compressor

Set screws all the way in. Set spindle break. Remove 17mm bolt.

Back T Nuts on spring compressor all the way out.

With fingers compress spring and move large washer to bottom.

Remove washer through bottom. Put spring back over two bolts.

Remove spring compressor 3 screws.

Home made spring compressor.

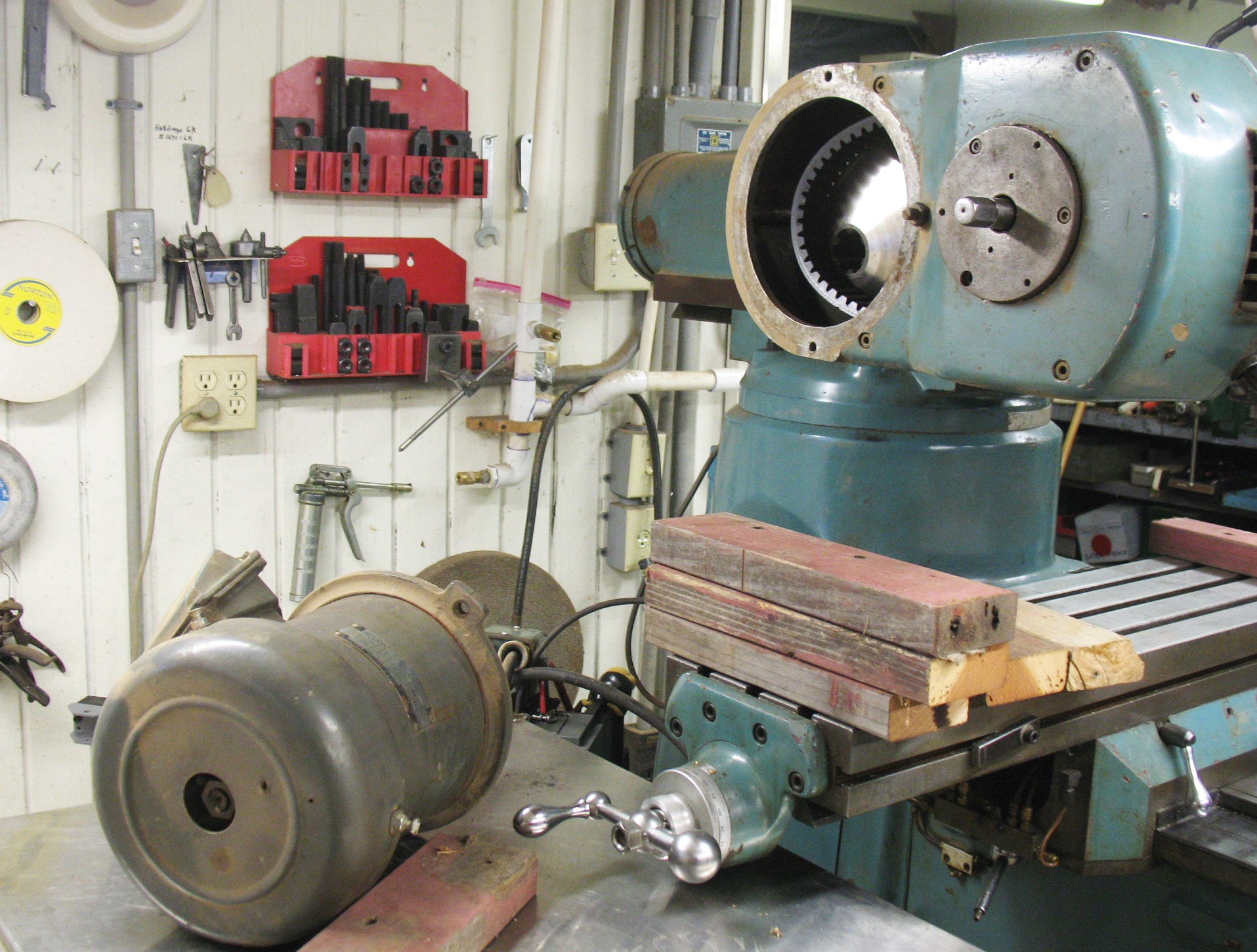

Remove motor.

Remove Speed control face plate. Unbolt 2 Screws on right.

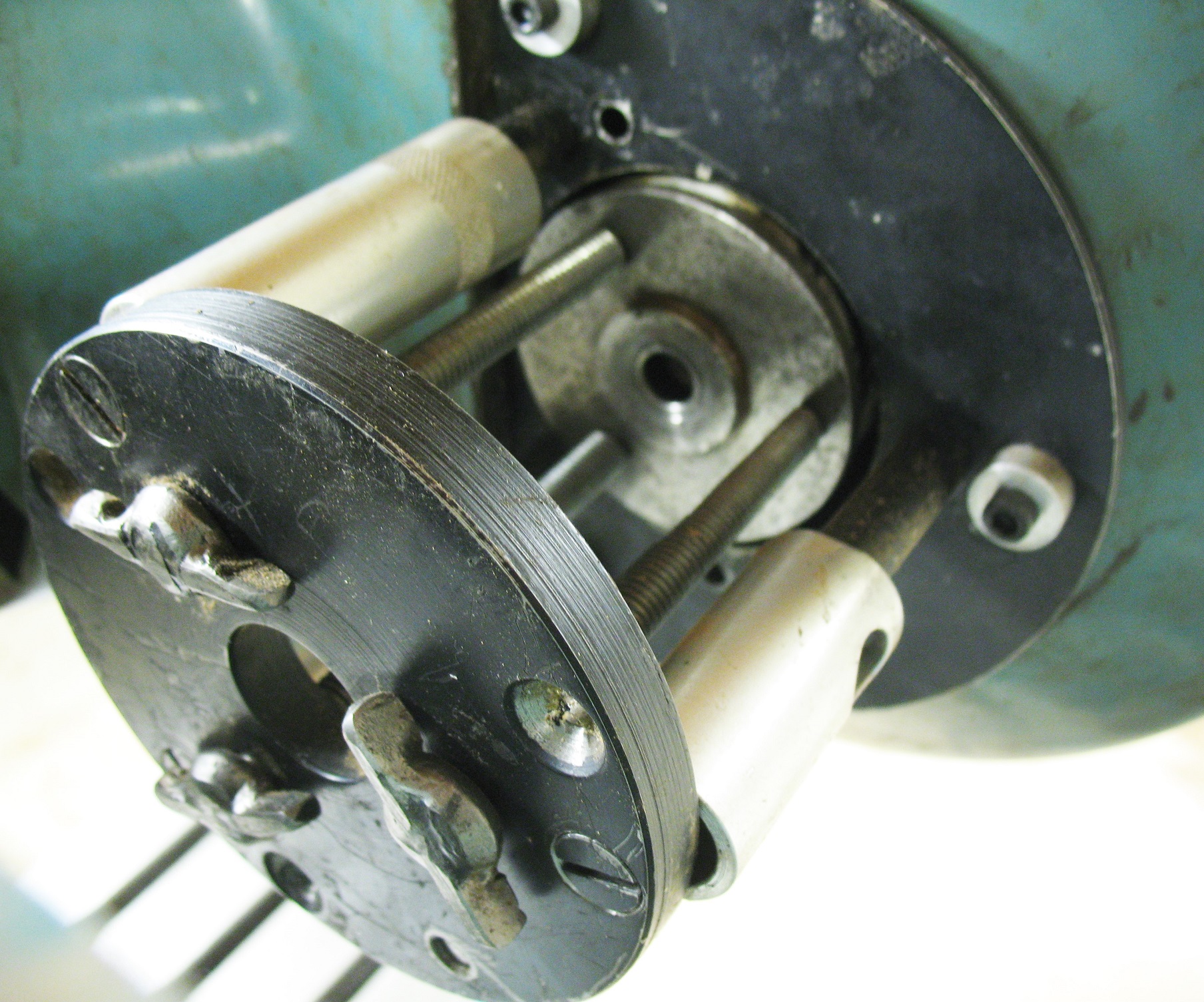

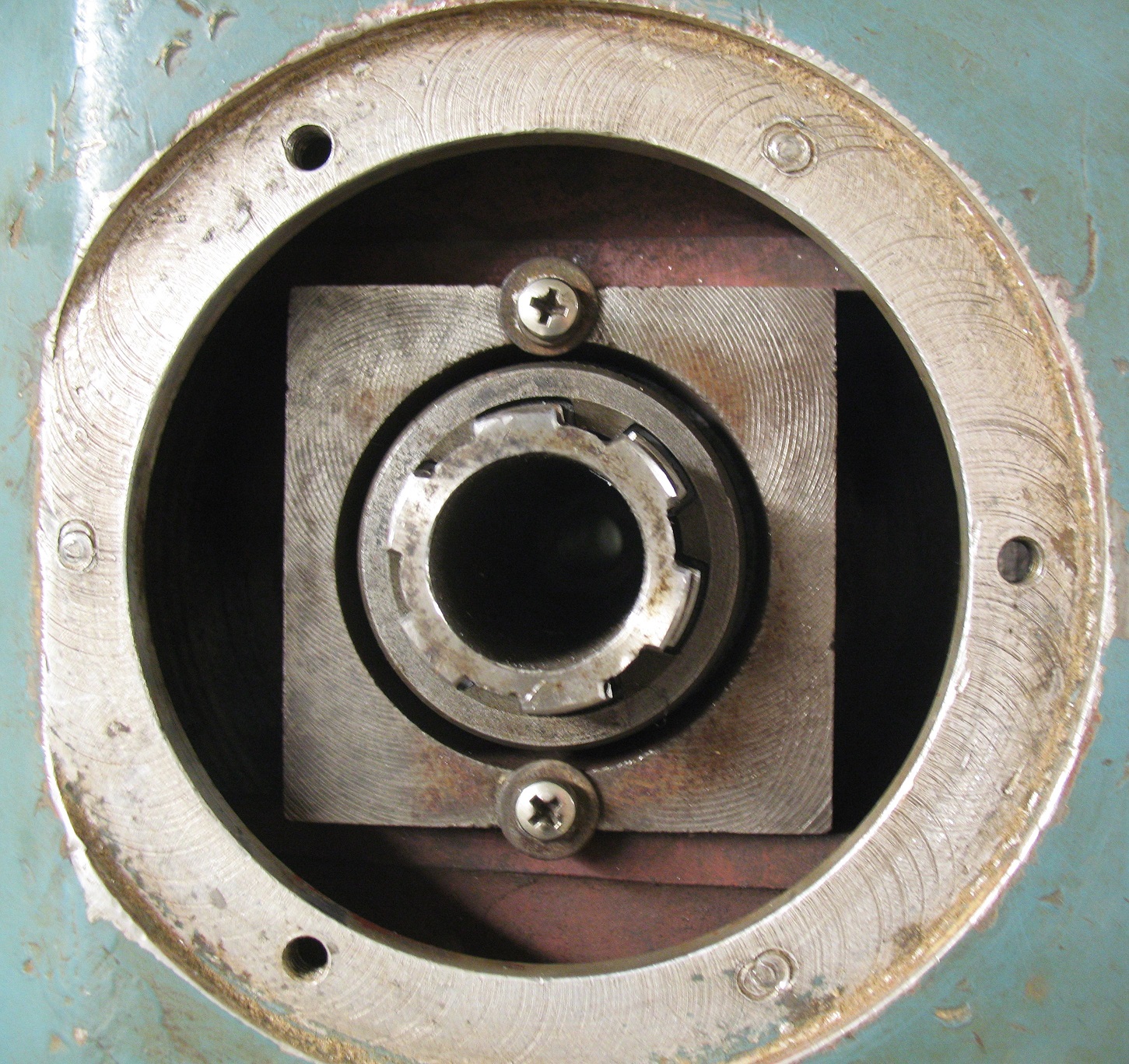

Unscrew 3 cap screw holding top bearing plate, use 3 screws to press

through plate and remove plate and bearing. Remove 2 screws holding

Speed control square block in pressure bar.

Remove Inspection plates. Remove 5 bolts in top case head.

Tap with rubber hammer to remove.

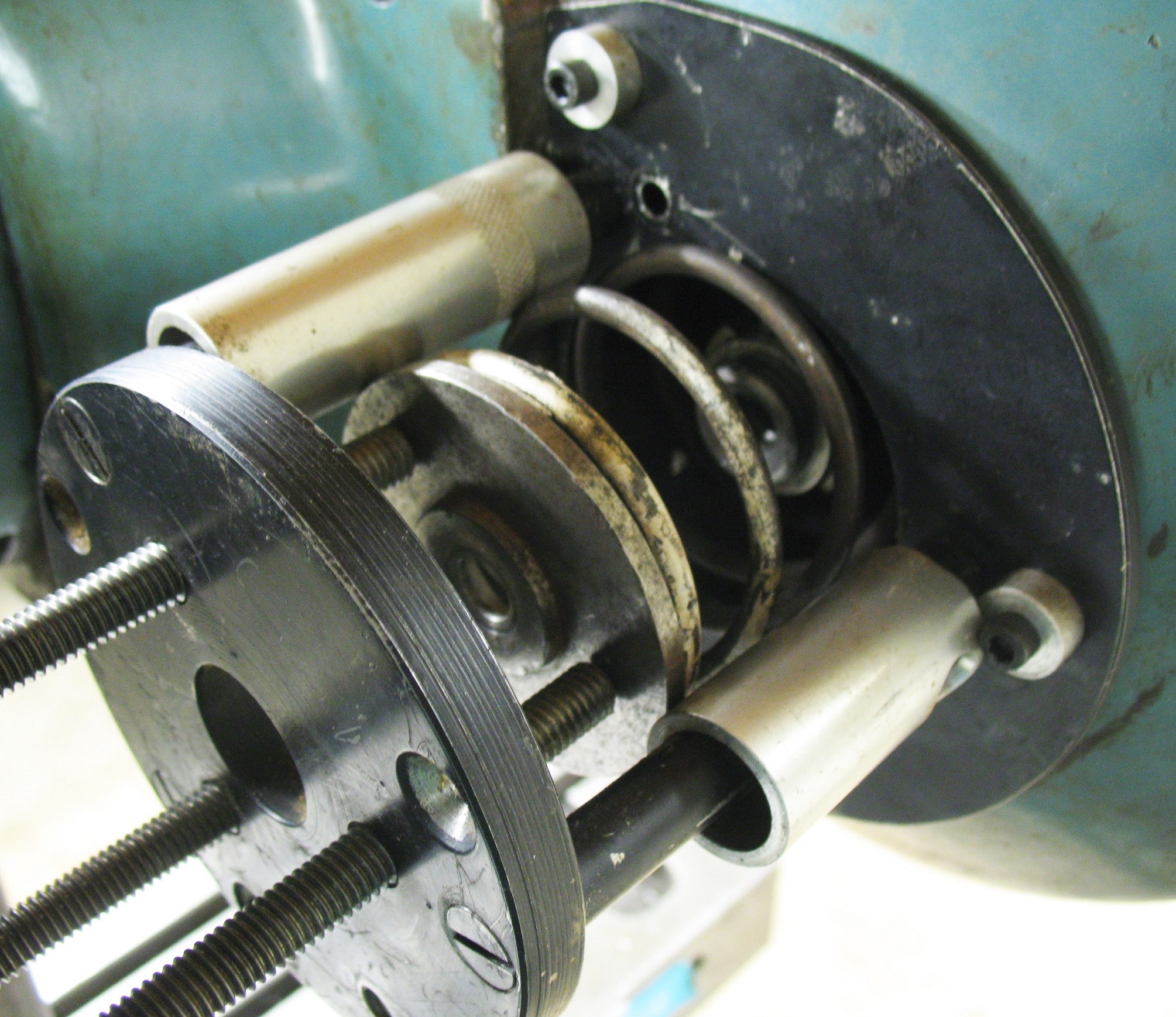

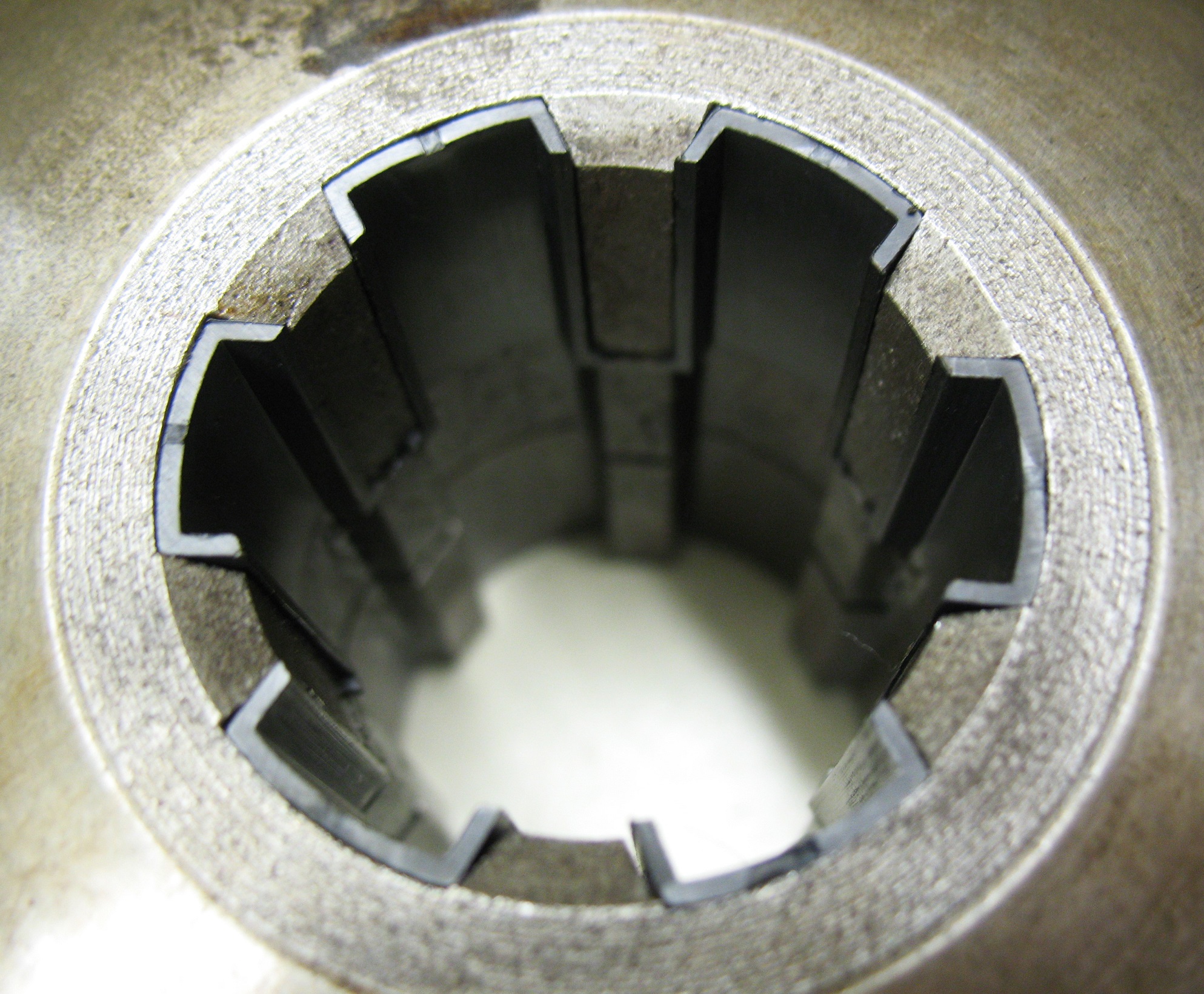

Clean Pulley, Clean groves inside pulley.

Clean splines on motor shaft. De Bur. Chamfer sides and top of

splines on Motor shaft and Both steps on Spindle shaft splines.

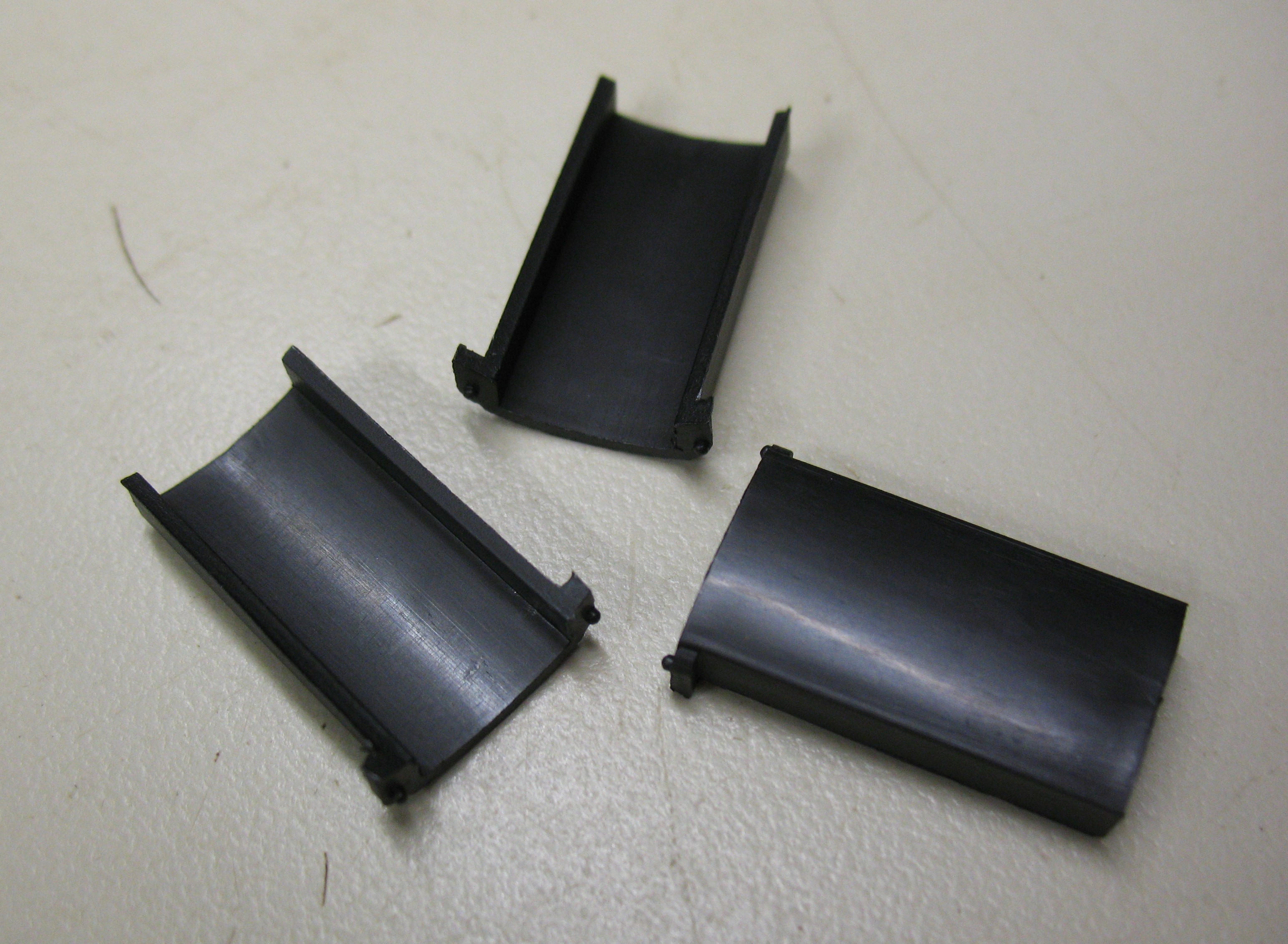

Plastic Inserts for Splines, over $4.00 each you need 24.

Be careful. With sharp exacto blade chamfer inside edges

of both ends.

Replace Plastic sleeves, notches go into groves on inside of the pulley.

__________________________________________

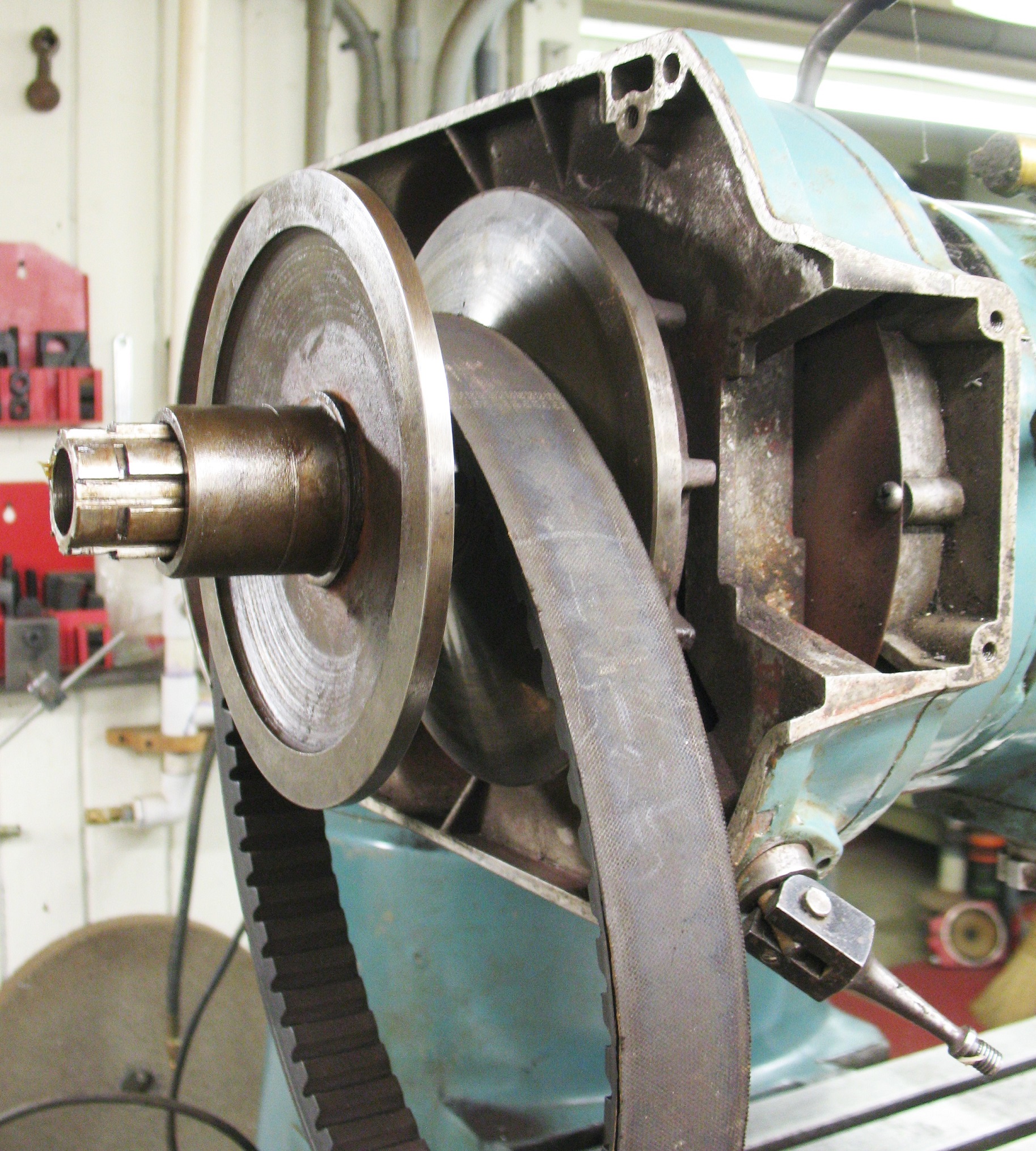

Replace spindle pulley on spindle.

Put belt over pulley.

Replace Top casting.

Replace square block in pressure bar.

Put motor pulley inside Top Casting behind belt.

Use knee to raise motor.

From right side, or bottom of head, put bottom motor

pulley on motor shaft.

Move motor into position and bolt on.

Mount Spring Compressor and compress spring.

Re mount motor pulley spring washer bolt.

Remove spring compressor.

Replace bottom cover.

Tilt head.

Tighten Head Bolts.

Holy Cow!